Page 948 - Ceratizit Catalog

P. 948

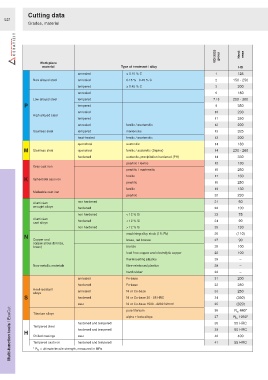

Cutting data

E21

Grades, material

VDI 3323 group Hard- ness

Work piece

material Type of treatment / alloy HB

annealed ≤ 0.15 % C 1 125

Non alloyed steel annealed 0.15 % - 0.45 % C 2 150 - 250

tempered ≥ 0.45 % C 3 300

annealed 6 180

Low alloyed steel tempered 7 / 8 250 - 300

P tempered 9 350

annealed 10 200

High alloyed steel

tempered 11 350

annealed ferritic / martensitic 12 200

Stainless steel tempered martensitic 13 325

heat-treated ferritic / martensitic 13 200

quenched austenitic 14 180

M Stainless steel quenched ferritic / austenitic (Duplex) 14 230 - 260

hardened austenitc, precipitation hardened (PH) 14 330

pearlitic / ferritic 15 180

Grey cast iron

pearlitic / martensitic 16 260

ferritic 17 160

K Spheroidal cast iron

pearlitic 18 250

ferritic 19 130

Malleable cast iron

pearlitic 20 230

non hardened 21 60

Aluminium

wrought alloys

hardened 22 100

non hardened < 12 % Si 23 75

Aluminium hardened < 12 % Si 24 90

cast alloys

non hardened > 12 % Si 25 130

machining alloy stock (1% Pb) 26 (110)

N

Copper and brass, red bronze 27 90

copper alloys (bronze,

brass) bronze 28 100

lead-free copper and electrolytic copper 28 100

thermosetting plastics 29 –

Non-metallic materials fibre-reinforced plastics 29 –

hard rubber 30 –

annealed Fe-base 31 200

hardened Fe-base 32 280

Heat-resistant

annealed Ni or Co-base 33 250

alloys

S hardened Ni or Co-base 30 - 58 HRC 34 (350)

(320)

cast Ni or Co-base 1500 - 2200 N/mm² 35 R 1050*

Multi-function tools / EcoCut H Tempered steel hardened and tempered 38 55 HRC

36

pure titanium

R 440*

m

Titanium alloys

37

alpha + beta alloys

m

60 HRC

hardened and tempered

39

cast

Chilled castings

40

400

hardened and tempered

41

Tempered cast iron

55 HRC

* R m = ultimate tensile strength, measured in MPa