Page 1033 - Tungaloy Catalog

P. 1033

Technical Reference

Solid Carbide Endmills

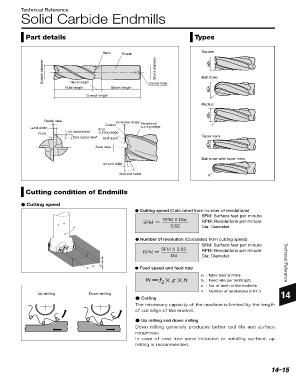

Part details Types

Neck Shank Square

Outside diameter Shank diameter Ball nose

øDc

Neck length

Flute length Shank length Center hole

øDc

Overall length

Radius

øDc

Radial rake Concave angle

Corner Peripheral

Land width End cutting edge

Flute 1st radial relief cutting edge

2nd radial relief End gash Taper neck

øDc1

Axial rake

Ball nose with taper neck

1st end relief

2nd end relief

Cutting condition of Endmills

Cutting speed

Cutting speed (Calculated from number of revolutions)

SFM: Surface feet per minute

31. 9 %JB RPM: Revolutions per minute

4'.

Dia: Diameter

Number of revolution (Calculated from cutting speed)

SFM: Surface feet per minute

4'. 9 RPM: Revolutions per minute

31.

%JB Dia: Diameter

Feed speed and feed rate Technical Reference

vf : Table feed (in/min)

fz : Feed rate per tooth (ipt)

z : No. of teeth of the endmills

n : Number of revolutions (min -1 )

Up milling Down milling 14

● Cutting

The necessary capacity of the machine is limited by the length

of cut edge of the endmill.

● Up milling and down milling

Down milling generally produces better tool life and surface

roughness.

In case of cast iron sand inclusion or welding surface, up

milling is recommended.

14–15