Page 1034 - Tungaloy Catalog

P. 1034

Technical Reference

Solid Carbide Endmills

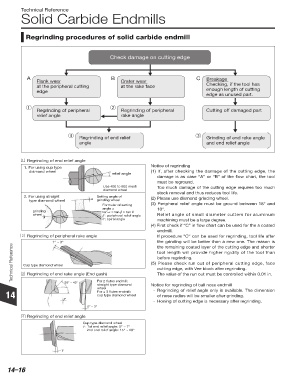

Regrinding procedures of solid carbide endmill

Check damage on cutting edge

A B C Breakage

Flank wear Crater wear

at the peripheral cutting at the rake face Checking, if the tool has

edge enough length of cutting

edge as unused part.

Regrinding of peripheral Regrinding of peripheral Cutting off damaged part

relief angle rake angle

Regrinding of end relief Grinding of end rake angle

angle and end relief angle

¡ Regrinding of end relief angle

1. For using cup type Notice of regrinding

diamond wheel (1) If, after checking the damage of the cutting edge, the

relief angle

damage is as case “A” or “B” of the flow chart, the tool

must be reground.

Use 400 to 600 mesh Too much damage of the cutting edge requires too much

diamond wheel

stock removal and thus reduces tool life.

2. For using straight α Setting angle of (2) Please use diamond grinding wheel.

type diamond wheel grinding wheel

Formular of setting (3) Peripheral relief angle must be ground between 18° and

angle α 10°.

grinding tan α = tan β x tan θ

wheel β : peripheral relief angle Relief angle of small diameter cutters for aluminum

θ : spiral angle machining must be a large degree.

(4) First check if “C” in flow chart can be used for the a coated

endmill.

™ Regrinding of peripheral rake angle If procedure “C” can be used for regrinding, tool life after

1° ~ 3° the grinding will be better than a new one. The reason is

Technical Reference £ Regrinding of end rake angle (End gash) (5) Please check run out of peripheral cutting edge, face

the remaining coated layer of the cutting edge and shorter

tool length will provide higher rigidity of the tool than

before regrinding.

Cup type diamond wheel

cutting edge, with Vee block after regrinding.

The value of the run out must be controlled within 0.01 in.

For 2 flutes endmill:

30° ~ 45°

straight type diamond Notice for regrinding of ball nose endmill

wheel - Regrinding of relief angle only is available. The dimension

14 For ≥ 3 flutes endmill: of nose radius will be smaller after grinding.

cup type diamond wheel

- Honing of cutting edge is necessary after regrinding.

0° ~ 3°

¢ Regrinding of end relief angle

Cup type diamond wheel

γ : 1st end relief angle: 5° ~ 7°

2nd end relief angle: 15° ~ 20°

γ

14–16