Page 686 - Tungaloy Catalog

P. 686

High Feed Milling Cutter

DOFEED 03/06

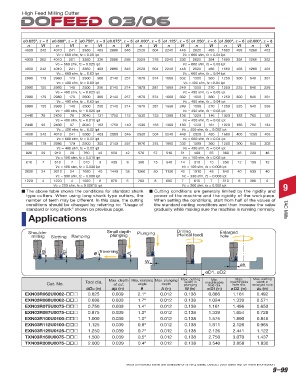

ø0.625", z = 2 ø0.688", z = 2 ø0.750", z = 3 ø0.875", z = 3 ø1.000", z = 5 ø1.125", z = 5 ø1.250", z = 6 ø1.500", z = 6 ø2.000", z = 8

n Vf n Vf n Vf n Vf n Vf n Vf n Vf n Vf n Vf

4030 242 4010 241 3360 403 2880 346 2520 504 2240 448 2020 485 1680 403 1260 403

Vc = 660 sfm, fz = 0.03 ipt Vc = 660 sfm, fz = 0.04 ipt

4030 202 4010 201 3360 336 2880 288 2520 378 2240 336 2020 364 1680 302 1260 302

Vc = 660 sfm, fz = 0.025 ipt Vc = 660 sfm, fz = 0.03 ipt

4030 242 4010 241 3360 403 2880 346 2520 504 2240 448 2020 485 1680 403 1260 403

Vc = 660 sfm, fz = 0.03 ipt Vc = 660 sfm, fz = 0.04 ipt

2990 179 2980 179 2500 300 2140 257 1870 374 1660 332 1500 360 1250 300 940 301

Vc = 490 sfm, fz = 0.03 ipt Vc = 490 sfm, fz =0.04 ipt

2990 150 2980 149 2500 250 2140 214 1870 281 1660 249 1500 270 1250 225 940 226

Vc = 490 sfm, fz = 0.025 ipt Vc = 490 sfm, fz = 0.03 ipt

2990 179 2980 179 2500 300 2140 257 1870 374 1660 332 1500 360 1250 300 940 301

Vc = 490 sfm, fz = 0.03 ipt Vc = 490 sfm, fz = 0.04 ipt

2990 150 2980 149 2500 250 2140 214 1870 281 1660 249 1500 270 1250 225 940 226

Vc = 490 sfm, fz = 0.025 ipt Vc = 490 sfm, fz = 0.03 ipt

2440 78 2430 78 2040 131 1750 112 1530 153 1360 136 1220 146 1020 122 760 122

Vc = 400 sfm, fz = 0.016 ipt Vc = 400 sfm, fz = 0.02 ipt

2440 98 2430 97 2040 163 1750 140 1530 168 1360 150 1220 161 1020 135 760 134

Vc = 400 sfm, fz = 0.02 ipt Vc = 400 sfm, fz = 0.022 ipt

4030 242 4010 241 3360 403 2880 346 2520 504 2240 448 2020 485 1680 403 1260 403

Vc = 660 sfm, fz = 0.03 ipt Vc = 660 sfm, fz = 0.04 ipt

2990 179 2980 179 2500 300 2140 257 1870 374 1660 332 1500 360 1250 300 940 302

Vc = 490 sfm, fz = 0.03 ipt Vc = 490 sfm, fz = 0.04 ipt

920 29 910 29 760 49 650 42 570 57 510 51 460 55 380 46 290 46

Vc = 150 sfm, fz = 0.016 ipt Vc = 150 sfm, fz = 0.02 ipt

610 7 610 7 510 9 430 8 380 15 340 14 310 15 250 12 190 12

Vc = 100 sfm, fz = 0.006 ipt Vc = 100 sfm, fz = 0.008 ipt

2020 24 2010 24 1680 40 1440 35 1260 50 1120 45 1010 48 840 40 630 40

Vc = 330 sfm, fz = 0.006 ipt Vc = 330 sfm, fz = 0.008 ipt

1220 4 1220 4 1020 6 870 5 760 8 680 7 610 7 510 6 380 6

Vc = 200 sfm, fz = 0.00015 ipt Vc = 200 sfm, fz = 0.002 ipt 9

The above table shows the conditions for standard shank Cutting conditions are generally limited by the rigidity and

type cutters. When using long shank type cutters, the power of the machine and the rigidity of the workpiece.

number of teeth may be different. In this case, the cutting When setting the conditions, start from half of the values of

conditions should be changed by referring to: “Usage of the standard cutting conditions and then increase the value

standard or long shank” shown on previous page. gradually while making sure the machine is running normally. TAC Mills

Applications

Shoulder Small depth Plunging Drilling Enlarged

milling Slotting Ramping plunging (Helical feed) hole

ap ap θ Traversing A

W

ae

øD1, øD2

Max.

Max. cutting

Min.

width in

width in

Cat. No. Tool dia. Max. depth Max. ramping Max. plunging Max. cutting machinable machinable enlarged hole

angle

depth

of cut

hole dia.

plunging

hole dia.

øDc (in) ap (in) θ A (in) W (in) øD1(in) øD2 (in) ae (in)

EXN03R062U0062-ooo 0.625 0.039 2.1º 0.012 0.138 0.866 1.181 0.492

EXN03R068U0062-ooo 0.688 0.039 1.7º 0.012 0.138 1.024 1.339 0.571

EXN03R075U0075-ooo 0.750 0.039 1.4º 0.012 0.138 1.181 1.496 0.650

EXN03R087U0075-ooo 0.875 0.039 1.2º 0.012 0.138 1.339 1.654 0.728

EXN03R100U0100-ooo 1.000 0.039 1.0º 0.012 0.138 1.575 1.890 0.846

EXN03R112U0100-ooo 1.125 0.039 0.8º 0.012 0.138 1.811 2.126 0.965

EXN03R125U0125-ooo 1.250 0.039 0.7º 0.012 0.138 2.126 2.441 1.122

TXN03R150U0075-ooo 1.500 0.039 0.5º 0.012 0.138 2.750 3.070 1.437

TXN03R200U0075-ooo 2.000 0.039 0.4º 0.012 0.138 3.540 3.858 1.830

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–99