Page 689 - Tungaloy Catalog

P. 689

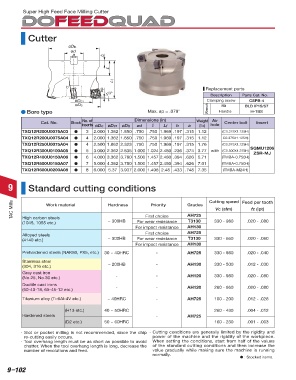

Super High Feed Face Milling Cutter

Cutter

øDb

ød

a b

R

Lf

ap Replacement parts

13º

Description Parts Cat. No.

Clamping screw CSPB-4

øDc1

øDc Bit BLD IP15/S7

Bore type Max. ap = .079" Wrench Handle H-TBS

Cat. No. Stock No. of Dimensions (in) Weight Air Center bolt Insert

inserts øDc øDc1 øDb ød r Lf b a (lb) hole

TXQ12R200U0075A03 d 3 2.000 1.362 1.850 .750 .750 1.969 .197 .315 1.12 (C0.375X1.125H)

TXQ12R200U0075A04 d 4 2.000 1.362 1.850 .750 .750 1.969 .197 .315 1.12 C0.375X1.125H)

TXQ12R250U0075A04 d 4 2.500 1.862 2.323 .750 .750 1.969 .197 .315 1.76 (C0.375X1.125H)

TXQ12R300U0100A05 d 5 3.000 2.362 2.835 1.000 1.024 2.480 .236 .374 3.77 with (C0.500X1.375H) SQMU1206

ZSR-MJ

TXQ12R400U0150A06 d 6 4.000 3.362 3.780 1.500 1.457 2.480 .394 .626 5.71 (TMBA-0.750H)

TXQ12R500U0150A07 d 7 5.000 4.362 3.780 1.500 1.457 2.480 .394 .626 7.01 (TMBA-0.750H)

TXQ12R600U0200A08 d 8 6.000 5.37 3.937 2.000 1.496 2.48 .433 .748 7.35 (TMBA-M24H)

9 Standard cutting conditions

TAC Mills Work material Hardness First choice Grades Cutting speed Feed per tooth

Priority

Vc (sfm)

fz (ipt)

AH725

High carbon steels

(1045, 1055 etc.) ~ 300HB For wear resistance T3130 330 - 980 .020 - .080

For impact resistance AH130

Alloyed steels First choice AH725

(4140 etc.) ~ 300HB For wear resistance T3130 330 - 660 .020 - .060

For impact resistance AH130

Prehardened steels (NAK80, PX5, etc.) 30 ~ 40HRC - AH725 330 - 660 .020 - .040

Stainless steel

(304, 316 etc.) ~ 200HB - AH130 330 - 500 .012 - .030

Gray cast iron

(No.25, No.30 etc.) - - AH120 330 - 980 .020 - .080

Ductile cast irons - AH120

(60-40-18, 65-45-12 etc.) - 260 - 660 .020 - .080

Titanium alloy (Ti-6Al-4V etc.) ~ 40HRC - AH725 100 - 200 .012 - .028

(H13 etc.) 40 ~ 50HRC 260 - 430 .004 - .012

Hardened steels - AH725

(D2 etc.) 50 ~ 60HRC 160 - 230 .001 - .003

· Slot or pocket milling is not recommended, since the chip · Cutting conditions are generally limited by the rigidity and

re-cutting easily occurs. power of the machine and the rigidity of the workpiece.

· Tool overhang length must be as short as possible to avoid When setting the conditions, start from half of the values

chatter. When the tool overhang length is long, decrease the of the standard cutting conditions and then increase the

number of revolutions and feed. value gradually while making sure the machine is running

normally.

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–102