Page 685 - Tungaloy Catalog

P. 685

DOFEED 03/06

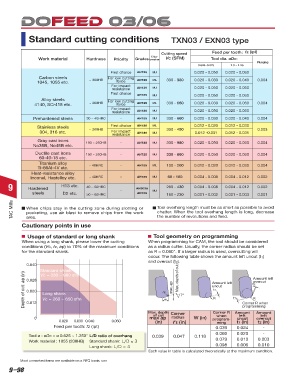

Standard cutting conditions TXN03 / EXN03 type

h: fz (ipt)

Cutting speed Feed per toot

Chip-

Work material Hardness Priority Grades breaker Vc (SFM) Tool dia. øDc:

Plunging

0.625~0.875 1.0 ~ 1.25

First choice AH725 MJ 0.020 - 0.050 0.020 - 0.060

Carbon steels For low cutting ML

1045, 1055 etc. ~ 300HB force AH725 330 - 980 0.020 - 0.030 0.020 - 0.040 0.004

For impact AH130 MJ

resistance 0.020 - 0.050 0.020 - 0.060

First choice AH725 MJ 0.020 - 0.050 0.020 - 0.060

Alloy steels For low cutting

4140, SCr415 etc. ~ 300HB force AH725 ML 330 - 660 0.020 - 0.030 0.020 - 0.060 0.004

For impact

resistance AH130 MJ 0.020 - 0.050 0.020 - 0.060

Prehardened steels 30 ~ 40HRC - AH725 MJ 330 - 660 0.020 - 0.030 0.020 - 0.040 0.004

Stainless steels ~ 200HB First choice AH130 ML 0.012 - 0.020 0.012 - 0.030

304, 316 etc. For impact AH130 MJ 330 - 490 0.012 -0.031 0.012 - 0.031 0.003

resistance

Gray cast irons

No35B, No45B etc. 150 ~ 250HB - AH725 MJ 330 - 980 0.020 - 0.050 0.020 - 0.060 0.004

Ductile cast irons 150 ~ 250HB - AH725 MJ 330 - 660 0.020 - 0.050 0.020 - 0.060 0.004

60-40-18 etc.

Titanium alloy - AH725 ML

Ti-66AI-4V etc. ~ 40HRC 100 - 200 0.012 - 0.020 0.012 - 0.030 0.004

Heat-resistance alloy

Inconel, Hastelloy etc. ~ 40HRC - AH725 MJ 60 - 160 0.004 - 0.006 0.004 - 0.012 0.002

9 Hardened H13 etc. 40 ~ 50HRC AH3035 260 - 430 0.004 - 0.008 0.004 - 0.012 0.002

steels D2 etc. 50 ~ 60HRC - AH725 MJ 160 - 230 0.001 - 0.002 0.001 - 0.003 0.001

TAC Mills When chips stay in the cutting zone during slotting or Tool overhang length must be as short as possible to avoid

chatter. When the tool overhang length is long, decrease

pocketing, use air blast to remove chips from the work

the number of revolutions and feed.

area.

Cautionary points in use

Usage of standard or long shank Tool geometry on programming

When using a long shank, please lower the cutting When programming for CAM, the tool should be considered

conditions (Vc, fz, ap) to 70% of the maximum conditions as a radius cutter. Usually, the corner radius should be set

for the standard shank. as R = 0.060". If a larger radius is used, overcutting will

occur. The following table shows the amount left uncut (t 1)

and overcut (t 2).

0.040

Standard shank Max. depth of cut Amount left

Depth of cut: ap (in) 0.020 Long shank rε w max. ap 17° Amount left t1 t2

Vc = 330 ~ 980 sfm

0.028

overcut

uncut

t1

R

R

Vc = 260 ~ 650 sfm

0.012

Corner R when

programming

Max. depth Corner Corner R Amount Amount

left

left

of cut

when

0 max ap radius W (in) program- uncut overcut

0.020 0.030 0.040 0.060 (in) rε (in) ming t1 (in) t2 (in)

Feed per tooth: fz (ipt) 0.039 0.024 -

0.060 0.020 -

Tool ø : øDc = ø 0.625 ~ 1.250" L/D ratio of overhang 0.039 0.047 0.118

Work material : 1055 (200HB) Standard shank: L/D ≤ 3 0.079 0.010 0.003

0.098 0.006 0.010

Long shank: L/D = 4

Each value in table is calculated theoretically at the maximum condition.

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–98