Page 693 - Tungaloy Catalog

P. 693

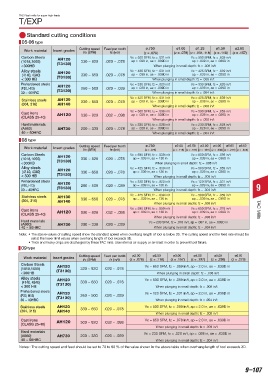

TAC Flash mills for super high feeds

T/EXP

Standard cutting conditions

05·06 type

Work material Insert grades Cutting speed Feed per tooth ø.750 ø1.00 ø1.25 ø1.50 ø2.00

Vc (SFM) fz (in/t) (z = .078) (z = .078) (z = .078, .118) (z = .118) (z = .157)

Carbon Steels AH120 Vc = 500 SFM, fz = .031 in/t Vc = 500 SFM, fz = .039 in/t

(1018,1055) (T3130) 330 ~ 820 .020 ~ .078 ap = .039 in, ae = .039D in ap = .039 in, ae = .039D in

< 300HB When plunging in small depth: fz = .008 in/t

Alloy steels AH120 Vc = 425 SFM, fz = .031 in/t Vc = 425 SFM, fz = .039 in/t

(4140, 4340) 330 ~ 650 .020 ~ .078 ap = .039 in, ae = .039D in ap = .039 in, ae = .039D in

< 300 HB (T3130) When plunging in small depth: fz = .008 in/t

Prehardened steels AH120 Vc = 330 SFM, fz = .020 in/t Vc = 330 SFM, fz = .020 in/t

(P20, H13) 260 ~ 500 .020 ~ .039 ap = .039 in, ae = .039D in ap = .039 in, ae = .039D in

30 ~ 40HRC (T3130) When plunging in small depth: fz = .004 in/t

Stainless steels AH130 330 ~ 650 .020 ~ .078 Vc = 425 SFM, fz = .031 in/t Vc = 425 SFM, fz = .039 in/t

ap = .039 in, ae = .039D in

ap = .039 in, ae = .039D in

(304, 316) AH140 When plunging in small depth: fz = .008 in/t

Vc = 500 SFM, fz = .039 in/t Vc = 590 SFM, fz = .059 in/t

Cast irons AH120 330 ~ 820 .032 ~ .098 ap = .039 in, ae = .039D in ap = .039 in, ae = .039D in

(CLASS 25-40)

When plunging in small depth: fz = .008 in/t

Hard materials Vc = 230 SFM, fz = .028 in/t Vc = 230 SFM, fz = .028 in/t

(A980) AH730 200 ~ 330 .020 ~ .078 ap = .028 in, ae = .039D in ap = .028 in, ae = .039D in

40 ~ 50HRC When plunging in small depth: fz = .004 in/t

08 type

Cutting speed Feed per tooth ø.750 ø2.00 ø2.50 ø3.00 ø4.00 ø5.00 ø6.00

Work material Insert grades

Vc (SFM) fz (in/t) (z = .078) (z = .118) (z = .157) (z = .197) (z = .236) (z = .275) (z = .315)

Carbon Steels AH120 Vc = 590 SFM, fz = .039 in/t Vc = 650 SFM, fz = .059 in/t

(1018,1055) (T3130) 330 ~ 820 .020 ~ .078 ap = .039 in, ae = 130 in ap = .039 in, ae = .039D in

< 300HB When plunging in small depth: fz = .008 in/t

Alloy steels Vc = 425 SFM, fz = .039 in/t Vc = 500 SFM, fz = .059 in/t

(4140, 4340) AH120 330 ~ 650 .020 ~ .078 ap = .039 in, ae = 130 in ap = .039 in, ae = .039D in

< 300 HB (T3130) When plunging in small depth: fz = .008 in/t

Prehardened steels AH120 Vc = 330 SFM, fz = .020 in/t Vc = 120 SFM, fz = .031 in/t

(P20, H13) (T3130) 260 ~ 500 .020 ~ .039 ap = .039 in, ae = 130 in ap = .039 in, ae = .039D in 9

30 ~ 40HRC When plunging in small depth: fz = .004 in/t

Stainless steels AH130 Vc = 425 SFM, fz = .039 in/t Vc = 500 SFM, fz = .059 in/t

ap = .039 in, ae = .039D in

ap = .039 in, ae = 130 in

(304, 316) AH140 330 ~ 650 .020 ~ .078

When plunging in small depth: fz = .008 in/t

Cast irons AH120 500 ~ 820 .032 ~ .098 Vc = 590 SFM, fz = .059 in/t Vc = 650 SFM, fz = .078 in/t TAC Mills

ap = .039 in, ae = 130 in

ap = .039 in, ae = .039D in

(CLASS 25-40)

When plunging in small depth: fz = .008 in/t

Hard materials Vc = 230 SFM, fz = .078 in/t, ap = .087 in, ae = .039D in

(A980) AH730 200 ~ 330 .020 ~ .039

40 ~ 50HRC When plunging in small depth: fz = .004 in/t

Note: • The above values of cutting speed show the standard speed when overhang length of tool is below 3D. The cutting speed and the feed rate should be

set at the lower limit values when overhang length of tool exceeds 3D.

• Thick and heavy chips are discharged by these TAC mills. Use internal air supply or air-blast in order to prevent tool failure.

09 type

Work material Insert grades Cutting speed Feed per tooth ø2.00 ø2.50 ø3.00 ø4.00 ø5.00 ø6.00

Vc (SFM) fz (in/t) (z = .078) (z = .118) (z = .157) (z = .197) (z = .236) (z = .275)

Carbon Steels AH120 Vc = 650 SFM, fz = .059 in/t, ap = 2.0 in, ae = .039D in

(1018,1055) (T3130) 330 ~ 820 .020 ~ .078

< 300HB When plunging in small depth: fz = .008 in/t

Alloy steels AH120 Vc = 500 SFM, fz = .059 in/t, ap = 2.0 in, ae = .039D in

(4140, 4340) 330 ~ 650 .020 ~ .078

< 300 HB (T3130) When plunging in small depth: fz = .008 in/t

Prehardened steels AH120 Vc = 120 SFM, fz = .031 in/t, ap = 2.0 in, ae = .039D in

(P20, H13) (T3130) 260 ~ 500 .020 ~ .039

30 ~ 40HRC When plunging in small depth: fz = .004 in/t

Stainless steels AH130 330 ~ 650 .020 ~ .078 Vc = 500 SFM, fz = .059 in/t, ap = 2.0 in, ae = .039D in

(304, 316) AH140

When plunging in small depth: fz = .008 in/t

Cast irons AH120 Vc = 650 SFM, fz = .078 in/t, ap = 2.0 in, ae = .039D in

(CLASS 25-40) 500 ~ 820 .032 ~ .098

When plunging in small depth: fz = .008 in/t

Hard materials Vc = 230 SFM, fz = .028 in/t, ap = .028 in, ae = .039D in

(A980) AH730 200 ~ 330 .020 ~ .039

40 ~ 50HRC When plunging in small depth: fz = .004 in/t

Notes : The cutting speed and feed should be set to 70 to 80 % of the value shown in the above table when overhang length of tool exceeds 3D.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–107