Page 694 - Tungaloy Catalog

P. 694

TAC Flash mills for super high feeds

T/EXP 10°, 20° Steel Stainless Cast Iron Materials

.002, .031in

Hard

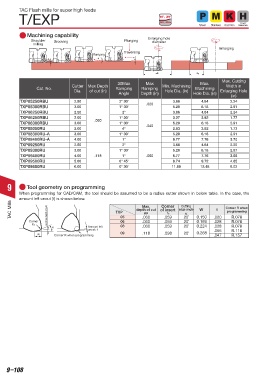

Machining capability

Shoulder Grooving Plunging Enlarging hole

Plunging

diameter

milling

Enlarging

Traversing

Ramping

a p θ A

øD a e

Max. Cutting

30Max Max Max.

Cutter Max Depth Min. Machining Width in

Cat. No. Ramping Ramping Machining

Dia. of cut (in) Hole Dia. (in) Enlarging Hole

Angle Depth (in) Hole Dia. (in)

(in)

TXP05250RBU 2.50 2° 30' 3.86 4.84 2.24

TXP05300RBU 3.00 1° 30' .020 5.20 6.18 2.91

TXP06250RBU 2.50 2° 3.86 4.84 2.24

TXP06200RBU 2.00 1° 30' 3.27 3.82 1.77

TXP06300RBU 3.00 .060 1° 30' 5.20 6.18 2.91

TXP08050RU 2.00 4° .040 2.83 3.82 1.73

TXP08300RU-A 3.00 1° 30' 5.20 6.18 2.91

TXP08400RU-A 4.00 1° 6.77 7.76 3.70

TXP09250RU 2.50 2° 3.86 4.84 2.20

TXP09300RU 3.00 1° 30' 5.20 6.18 2.87

TXP09400RU 4.00 .118 1° .060 6.77 7.76 3.66

TXP09500RU 5.00 0° 45' 8.74 9.72 4.65

TXP09600RU 6.00 0° 30' 11.50 12.48 6.02

9 Tool geometry on programming

When programming for CAD/CAM, the tool should be assumed to be a radius cutter shown in below table. In the case, the

amount left uncut (t) is shown below.

TAC Mills TXP depth of cut of insert edge angle W t Corner R when

Cutting

Corner

Max.

programming

κ

ap

rε

0.169

20˚

.028

06

Corner ap (Max depth of cut) 05 .060 .059 20˚ 0.150 .020 R.078

.060

.059

R.078

rε 0.224

κ Amount left 08 .060 .059 20˚ .028 R.078

uncut: t .055 R.118

09 .118 .098 20˚ 0.268

W Corner R when programming .047 R.157

Most unmarked items are available on a RFQ basis, contact your sales rep for more information. : Stocked items.

9–108