Page 698 - Tungaloy Catalog

P. 698

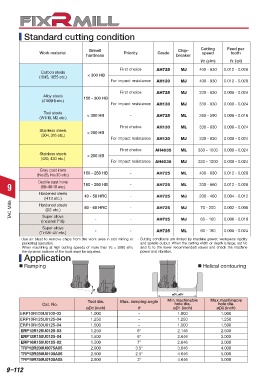

Standard cutting condition

Brinell Chip- Cutting Feed per ø1.250 ø1.500 ø2.000 ø2.500

Work material Priority Grade speed tooth

hardness breaker Vf Vf

Vc (sfm) fz (ipt) n Vf n ERP12 ERP16 n Vf n TRP12 TRP16

1790 110 1430 120 60 1150 110 910 110 90

First choice AH725 MJ 400 - 830 0.012 - 0.028

Carbon steels Vc = 590 sfm, fz = 0.020 ipt

(1045, 1055 etc.) < 300 HB 1790 110 1430 120 60 1150 110 910 110 90

For impact resistance AH130 MJ 400 - 830 0.012 - 0.028

Vc = 590 sfm, fz = 0.020 ipt

1690 80 1350 90 45 1080 85 860 80 70

First choice AH725 MJ 330 - 830 0.008 - 0.024

Alloy steels 150 - 300 HB Vc = 560 sfm, fz = 0.016 ipt

(4140(H) etc.) 1690 80 1350 90 45 1080 85 860 80 470

For impact resistance AH130 MJ 330 - 830 0.008 - 0.024

Vc = 560 sfm, fz = 0.016 ipt

Tool steels 1290 45 1030 50 25 830 50 660 45 40

(W1-10, M2 etc.) < 300 HB - AH725 ML 260 - 590 0.008 - 0.016 Vc = 560 sfm, fz = 0.012 ipt

1690 80 1350 90 45 1080 52 860 80 70

First choice AH130 ML 330 - 830 0.008 - 0.024

Stainless steels < 200 HB Vc = 560 sfm, fz = 0.016 ipt

(304, 316 etc.) 1690 80 1350 90 45 1080 52 860 80 70

For impact resistance AH130 MJ 330 - 830 0.008 - 0.024

Vc = 560 sfm, fz = 0.016 ipt

1990 95 1590 110 55 1270 100 1010 95 80

First choice AH4035 ML 330 - 1000 0.008 - 0.024

Stainless steels < 200 HB Vc = 660 sfm, fz = 0.016 ipt

(420, 430 etc.) 1990 95 1590 110 55 1270 100 1010 95 80

For impact resistance AH4035 MJ 330 - 1000 0.008 - 0.024

Vc = 660 sfm, fz = 0.016 ipt

Gray cast irons 1790 110 1430 120 60 1150 110 910 110 90

(No.25, No.30 etc.) 150 - 250 HB - AH725 ML 400 - 830 0.012 - 0.028 Vc = 590 sfm, fz = 0.020 ipt

Ductile cast irons 150 - 250 HB - 330 - 660 0.012 - 0.028 1490 90 1190 100 50 950 90 760 90 75

9 (60-40-18 etc.) AH725 ML Vc = 500 sfm, fz = 0.020 ipt

Hardened steels 990 25 800 25 15 640 25 510 25 20

(H13 etc.) 40 - 50 HRC - AH725 MJ 200 - 460 0.004 - 0.012 Vc = 330 sfm, fz = 0.008 ipt

TAC Mills Hardened steels 50 - 60 HRC - AH725 MJ 70 - 200 0.002 - 0.008 400 10 320 10 Vc = 330 sfm, fz = 0.008 ipt 10 200 10 8

250

5

(D2 etc.)

Super alloys

(Inconel 718) - - AH725 MJ 60 - 160 0.006 - 0.010

Super alloys

(Ti-6Al-4V etc.) - - AH725 ML 60 - 180 0.008 - 0.024

· Use air blast to remove chips from the work area in slot milling or · Cutting conditions are limited by machine power, workpiece rigidity

pocketing operation. and spindle output. When the cutting width or depth is large, set Vc

· When machining at high cutting speeds of more than Vc = 3280 sfm, and fz to the lower recommended values and check the machine

the dynamic balance of the tools must be adjusted. power and vibration.

Application

Ramping Helical contouring

θ

øD1, øD2

Tool dia. Max. ramping angle Min.machinable Max.machinable

Cat. No. hole dia. hole dia.

øDc (inch) θ øD1 (inch) øD2 (inch)

ERP10R100U0100-02 1.000 - 1.000 1.000

ERP10R125U0125-04 1.250 - 1.250 1.250

ERP10R150U0125-04 1.500 - 1.500 1.500

ERP12R125U0125-03 1.250 8° 2.146 2.500

ERP12R150U0125-04 1.500 6° 2.646 3.000

ERP16R150U0125-02 1.500 7° 2.646 3.000

TRP12R200U0075A05 2.000 3.5° 3.646 4.000

TRP12R250U0100A06 2.500 2.5° 4.646 5.000

TRP16R250U0100A05

3°

2.500

Most unmarked items are available on a RFQ basis, contact your sales rep for more information. 4.646 5.000

9–112