Page 701 - Tungaloy Catalog

P. 701

TRC / ERC type

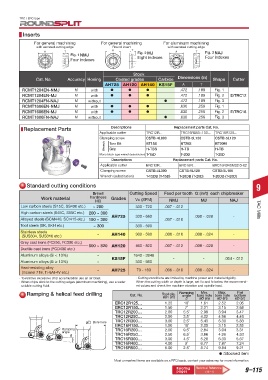

Inserts

For general machining For general machining For aluminum machining

with serrated cutting edge Round insert with serrated cutting edge

A T

A T Fig. 2 MJ A T Fig. 3 NAJ

Fig. 1 NMJ Eight indexes Four indexes

Four indexes

Stock

Cat. No. Accuracy Honing Coated grades Carbide Dimensions (in) Shape Cutter

AH725 AH120 AH140 KS15F A T

RCMT1204EN-NMJ M with .472 .189 Fig. 1

RCMT1204EN-MJ M with .472 .189 Fig. 2 E/TRC12

RCMT1204FN-NAJ M without .472 .189 Fig. 3

RCMT1606EN-NMJ M with .630 .256 Fig. 1

RCMT1606EN-MJ M with .630 .256 Fig. 2 E/TRC16

RCMT1606FN-NAJ M without .630 .256 Fig. 3

Replacement Parts Descriptions Replacement parts Cat. No.

Applicable cutter TRC12R... TRC16R050~100... TRC16R125...

Clamping screw CSTB-4L090 CSTB-5L120 CSTB-5L120

Wrench Torx Bit BT15S BT20S BT20M

Grip H-TBS H-TB H-TB

Mono block type wrench (substitution) T-15D T-20D T-20D

Descriptions Replacement parts Cat. No.

Applicable cutter ERC12R... ERC16R... ERC16R040M32.0-02

Clamping screw CSTB-4L090 CSTB-5L120 CSTB-5L105

Wrench (substitution) T-15DB (T-15D) T-20DB (T-20D) T-20DB (T-20D)

Standard cutting conditions 9

Brinell Cutting Speed Feed per tooth fz (in/t) each chipbreaker

Work material hardness Grades Vc (SFM)

HB NMJ MJ NAJ

Low carbon steels (S15C, SS400 etc.) ~ 200 330 - 720 .007 - .012

High carbon steels (S45C, S55C etc.) 200 ~ 300 TAC Mills

Alloyed steels (SCM440, SCr415 etc.) 150 ~ 300 AH725 330 - 660 .007 - .010 .008 - .028 -

Tool steels (SK, SKH etc.) ~ 300 330 - 590

Stainless steels - AH140

(SUS304, SUS316 etc.) 300 - 590 .006 - .010 .008 - .024 -

Grey cast irons (FC250, FC300 etc.)

500 ~ 820 AH120 460 - 820 .007 - .012 .008 - .028 -

Ductile cast irons (FCD400 etc.)

Aluminum alloys (Si < 13%) - KS15F 1640 - 3940 - - .004 - .012

Aluminum alloys (Si ≥ 13%) - 330 - 980

Heat-resisting alloy - AH725 70 - 160 .006 - .010 .008 - .024 -

(Inconel 718, Ti-6Al-4V etc.)

· To remove excessive chip accumulation use an air blast. · Cutting conditions are limited by machine power and material rigidity.

· When chips stick to the cutting edges (aluminum machining), use a water When the cutting width or depth is large, set Vc and fz below the recommend-

soluble cutting fluid. ed values and check the machine vibration and spindle load.

Max.

Flat

Min.

Ramping & helical feed drilling Cat. No. Tool dia. Ramping bore hole bore hole bottom

angle

øD1 (in)

øD (in)

øD (in)

øD (in)

θ

ERC12R125… 1.25 10˚ 1.61 2.52 2.05

ERC12R150… 1.50 7˚ 2.21 3.15 2.68

TRC12R200… 2.00 5.5˚ 2.99 3.94 3.47

TRC12R250… 2.50 3.5˚ 4.02 4.96 4.49

øD Bore hole TRC12R300… 3.00 2.5˚ 5.43 6.30 5.83

ERC16R150… 1.50 16˚ 2.05 3.15 2.52

Ramping TRC16R200… 2.00 9.5˚ 2.84 3.94 3.31

angle

θ TRC16R250… 2.50 6.5˚ 3.86 4.96 4.33

TRC16R300… 3.00 4.5˚ 5.20 6.30 5.67

TRC16R400… 4.00 3˚ 6.77 7.87 7.24

TRC16R500… 5.00 2.5˚ 8.74 9.84 9.21

:Stocked item

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–115

pages (14-1)