Page 703 - Tungaloy Catalog

P. 703

TAC Flash radius mills

TRD12 16, ERD12

•

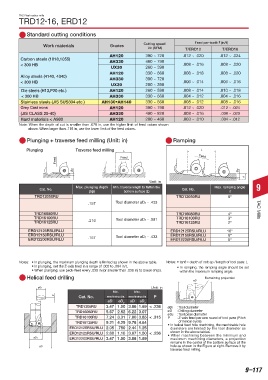

Standard cutting conditions

Work materials Grades Cutting speed Feed per tooth f (in/t)

Vc (SFM) T/ERD12 T/ERD16

AH120 390 ~ 720 .012 ~ .020 .012 ~ .024

Carbon steels (1018,1055) AH330 460 ~ 790

< 300 HB .008 ~ .016 .008 ~ .020

UX30 260 ~ 390

AH120 330 ~ 660 .008 ~ .018 .008 ~ .020

Alloy steels (4140, 4340) AH330 390 ~ 720

< 300 HB .006 ~ .014 .006 ~ .016

UX30 200 ~ 390

Die steels (H13,P20 etc.) AH120 260 ~ 590 .008 ~ .014 .010 ~ .018

< 300 HB AH330 330 ~ 660 .004 ~ .012 .004 ~ .016

Stainless steels (JIS SUS304 etc.) AH130•AH140 330 ~ 660 .008 ~ .012 .008 ~ .016

Grey Cast irons AH120 390 ~ 790 .012 ~ .020 .012 ~ .024

(JIS CLASS 25-40) AH330 490 ~ 820 .008 ~ .016 .008 ~ .020

Hard materials < A980 AH120 200 ~ 460 .003 ~ .010 .004 ~ .012

Note: When the depth of cut is smaller than .078 in, use the higher limit of feed values shown

above. When larger than .118 in, use the lower limit of the feed values.

Plunging + traverse feed milling (Unit: in) Ramping

Plunging Traverse feed milling L L

Feed Feed Feed

ap ap

θ

Unit: in

Max. plunging depth Min. traverse length to flatten the Max. ramping angle 9

Cat. No. Cat. No.

(ap) bottom surface (L) θ

TRD12050RU TRD12050RU 8º

Tool diameter øD1 - .433

.157

TRD16080RU TRD16080RU 4º TAC Mills

TRD16100RU Tool diameter øD1 - .591 TRD16100RU 3º

TRD16125RU .216 TRD16125RU 2º

ERD12125RSU/RLU ERD12125RSU/RLU 16º

ERD12150RSU/RLU Tool diameter øD1 - .433 ERD12150RSU/RLU 8º

ERD12200RSU/RLU .157 ERD12200RSU/RLU 6º

Notes: • In plunging, the maximum plunging depth is limited as shown in the above table. Notes: • tanθ = depth of cut: ap / length of tool pass: L

• In plunging, set the Z-axis feed in a range of .002 to .004 in/t. • In ramping, the ramping angle should be set

• When plunging, use peck-feed every .039 in (or smaller than .039 in) to break chips. within the maximum ramping angle.

Helical feed drilling Remaining projection

øD

P

øD2 Unit: in

Min. Max.

P

Cat. No. machining dia. machining dia P

øD øD 2 øD øD 2

TRD1205RU 3.47 1.50 3.86 1.89 < .236 øD1 : Tool diameter

TRD16080RU 5.67 2.52 6.22 3.07 øD : Drilling diameter

øD2 : Tool pass diameter

TRD16100RU 7.24 3.31 7.80 3.85 < .315 P : Z-axis feed per one round of tool pass (Pitch

of helical cycle)

TRD16125RU 9.21 4.29 9.76 4.84 • In helical feed hole machining, the machinable hole

ERD12125RSU/RLU 2.05 .750 2.44 1.25 diameters are limited by the tool diameter as

shown in the above tables.

ERD12125RSU/RLU 2.68 1.10 3.07 1.50 < .236 • When machining between the minimum and

øD1 ERD12200RSU/RLU 3.47 1.50 3.86 1.89 maximum machining diameters, a projection

remains in the center of the bottom surface of the

øD hole as shown in the Figure at right. Remove it by

traverse feed milling.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–117