Page 707 - Tungaloy Catalog

P. 707

TAC Flash endmills with center cutting edge

EVX

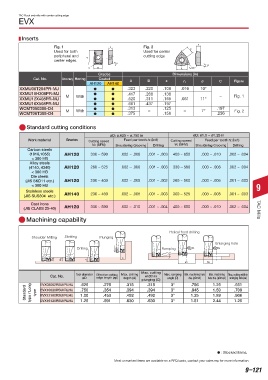

Inserts

s

Fig. 1 s Fig. 2

Used for both Used for center C

peripheral and A cutting edge

center edges

θ

θ°

r ε B r ε .032

A

Grades Dimensions (in)

Cat. No. Accuracy Honing Coated A B s θ C Figure

AH120 AH140 rε

XXMU08T204PR-MJ .323 .220 .109 .016 10°

XXMU10H308PR-MJ .417 .268 .138 Fig. 1

XXMU12X408PR-MJ M With .520 .311 .165 .031 11° -

XXMU16X508PR-MJ .661 .437 .197

WCMT050308-D4 M With .313 - .125 - 7° .197

WCMT06T308-D4 .375 .156 .236 Fig. 2

Standard cutting conditions

øD: ø.625 ~ ø.750 in øD: ø1.0 ~ ø1.25 in

Work material Grades Cutting speed Feed per tooth fz (in/t) Cutting speed Feed per tooth fz (in/t)

Vc (SFM) Shouldering·Grooving Drilling Vc (SFM) Shouldering·Grooving Drilling

Carbon steels

(1018,1055) AH120 330 ~ 590 .002 ~ .008 .001 ~ .003 400 ~ 650 .003 ~ .010 .002 ~ .004

< 300 HB

Alloy steels

(4140, 4340) AH120 260 ~ 525 .002 ~ .006 .001 ~ .003 330 ~ 590 .003 ~ .008 .002 ~ .004

< 300 HB

Die steels

(JIS SKD11 etc.) AH120 200 ~ 400 .002 ~ .005 .001 ~ .002 260 ~ 500 .003 ~ .006 .001 ~ .003

< 300 HB 9

Stainless steels

(JIS SUS304 etc.) AH140 230 ~ 460 .002 ~ .006 .001 ~ .003 300 ~ 525 .003 ~ .008 .001 ~ .003

Cast irons

(JIS CLASS 25-40) AH120 330 ~ 590 .002 ~ .010 .001 ~ .004 400 ~ 650 .003 ~ .010 .002 ~ .004 TAC Mills

Machining capability

Helical feed drilling

Shoulder Milling Slotting Plunging

Enlarging hole

Drilling Ramping

θ

a p a p A C

øD ae

Max. cutting

Tool diameter Effective cutting Max. drilling Max. ramping Min. machining hole Max. machining Max. cutting width in

Cat. No. width in

øD edge length (ap) depth (A) angle (D) dia. (øDmin) hole dia. (øDmax) enlarging hole (ae)

plunging (C) 3° .756 1.25 .551

.315

.625

.276

.315

EVX08062RSU/RLHU

Standard type / Long type EVX10020RSU/RLHU .750 .354 .394 .394 3° .945 1.50 .709

1.89

.906

3°

1.25

.453

.492

1.00

.492

EVX12100RSU/RLHU

2.44

.630

.630

1.25

1.25

1.51

EVX16125RSU/RLHU

.591

3°

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–121