Page 709 - Tungaloy Catalog

P. 709

TAC Flash endmills

ESD10

Inserts

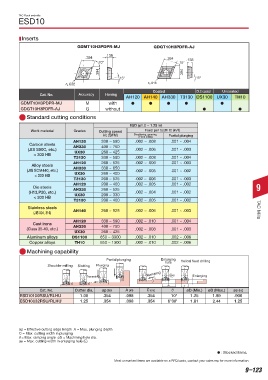

GDMT10H3PDPR-MJ GDGT10H3PDFR-AJ

.138

.394 .394 .138

70° 70°

.394 .394

15° 15°

r ε .032 r ε .016

Coated DLC coated Uncoated

Cat. No. Accuracy Honing

AH120 AH140 AH330 T3130 DS1100 UX30 TH10

GDMT10H3PDPR-MJ M with

GDGT10H3PDFR-AJ G without

Standard cutting conditions

ESD (ø1.0 ~ 1.25 in)

Work material Grades Cutting speed Feed per tooth fz (in/t)

Vc (SFM) Shouldering, grooving, Partial plunging

Z-feed milling

AH120 330 ~ 590 .002 ~ .008 .001 ~ .004

Carbon steels 400 ~ 750

(JIS S50C, etc.) AH330 260 ~ 425 .002 ~ .006 .001 ~ .003

< 300 HB UX30

T3130 330 ~ 590 .002 ~ .008 .001 ~ .004

AH120 260 ~ 525 .002 ~ .006 .001 ~ .003

Alloy steels

(JIS SCM440, etc.) AH330 330 ~ 650 .002 ~ .005 .001 ~ .002

< 300 HB UX30 260 ~ 400

T3130 260 ~ 525 .002 ~ .006 .001 ~ .003

AH120 200 ~ 400 .002 ~ .005 .001 ~ .002

Die steels 260 ~ 525 9

(H13,P20, etc.) AH330 200 ~ 330 .002 ~ .004 .001 ~ .002

UX30

< 300 HB

T3130 200 ~ 400 .002 ~ .005 .001 ~ .002

Stainless steels

(JIS 304, 316) AH140 260 ~ 525 .002 ~ .006 .001 ~ .003 TAC Mills

AH120 330 ~ 590 .002 ~ .010 .001 ~ .004

Cast irons

(Class 25-40, etc.) AH330 400 ~ 750 .002 ~ .008 .001 ~ .003

UX30 260 ~ 425

Aluminum alloys DS1100 650 ~ 3300 .002 ~ .010 .002 ~ .006

Copper alloys TH10 650 ~ 1300 .002 ~ .010 .002 ~ .006

Machining capability

Partial plunging Enlarging Helical feed drilling

hole

Shoulder milling Slotting Plunging

Ramping

Traversing Enlarging

C θ

A

ap ap

øD ae

Cat. No. Cutter dia. ap (in) A (in) C (in) θ øD (Min.) øD (Max.) ae (in)

ESD10100RSU/RLHU 1.00 .354 .098 .354 10° 1.25 1.89 .906

ESD10032RSU/RLHU 1.25 .354 .098 .354 6°30' 1.81 2.44 1.25

ap = Effective cutting edge length A = Max. plunging depth

C = Max. cutting width in plunging

θ = Max. ramping angle øD = Machining hole dia.

ae = Max. cutting width in enlarging hole (E)

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–123