Page 711 - Tungaloy Catalog

P. 711

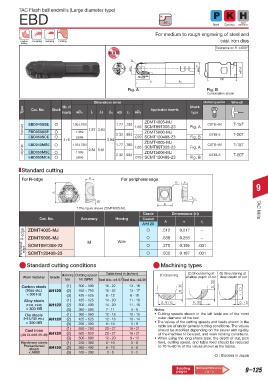

TAC Flash ball endmills (Large diameter type)

EBD R ~ 25 in Steel Cast Iron Materials

Hard

For medium to rough engraving of steel and

R

Radius Pocketing Ramping Profiling cast iron dies

Milling

Tolerance on R ±.008”

r ε

øDc h6 øDs ø50.8

ap cutting edge

length

100

L f R s

L

Fig. A Fig. B

Combination shank

Dimensions (mm) Clamping screw Wrench

No. of

Type Cat. No. Stock inserts øDc L Lf R s ap rε øDs Applicable inserts Shank

type

ZDMT4005-MJ CSTB-4M T-15T

1.56 (.780)

EBD040SSE

1.77 .780

Standard EBD050SSE 1.969 7.87 3.94 1.65 SCMT09T308-23 Fig. A

ZDMT5006-MJ

EBD050SCE (.984) 2.32 .984 .079 SCMT120408-23 Fig. B CSTB-5 T-20T

4+6 3.94 ZDMT4005-MJ T-15T

Long shank EBD040MSE 1.56 (.780) 9.84 5.91 1.77 .780 1.65 SCMT09T308-23 Fig. A CSTB-4M

EBD050MSE

ZDMT5006-MJ

1.969

EBD050MCE (.984) 2.32 .984 .079 SCMT120408-23 Fig. B CSTB-5 T-20T

Standard cutting

For R-edge For peripheral edge

r ε s

9

7°

A

* The figure shows ZDMT4005-MJ. TAC Mills

Grade Dimensions (in)

Cat. No. Accuracy Honing Coated

AH120 A s rε

R-edge ZDMT4005-MJ With .512 0.217 -

ZDMT5006-MJ

-

.638

0.256

Peripheral edge SCMT09T308-23 M .375 0.156 .031

.500

SCMT120408-23

0.187

.031

Standard cutting conditions Machining types

Table feed vf (in/min) (2) Shouldering at (3) Shouldering at

Work material Grade Machining Cutting speed (1) Grooving shallow depth of cut deep depth of cut

type Vc (SFM) Tool dia.: ø1.57Tool dia.: ø2.00

Carbon steels (1) 500 ~ 690 16 - 22 13 - 18

(1055 etc.) AH120 (2) 550 ~ 750 16 - 22 13 - 17

< 300 HB (3) 425 ~ 625 8 - 12 6 - 10

Alloy steels (1) 425 ~ 625 14 - 20 11 - 16

(4140, 4340) AH120 (2) 500 ~ 690 14 - 20 11 - 16

< 300 HB (3) 360 ~ 560 7 - 11 5 - 9 Notes:

Die steels (1) 360 ~ 560 12 - 18 10 - 15 • Cutting speeds shown in the left table are of the most

(H13,P20 etc.) AH120 (2) 425 ~ 625 12 - 18 10 - 14 outer diameter of the tool.

< 300 HB (3) 295 ~ 500 6 - 10 5 - 8 • The values of the cutting speeds and feeds shown in the

(1) 550 ~ 750 20 - 27 16 - 21 table are of under general cutting conditions. The values

Cast irons should be modified depending on the power and rigidity

(JIS CLASS 25-40) AH120 (2) 625 ~ 820 20 - 27 16 - 21 of the machine to be used, and work holding conditions.

(3) 500 ~ 690 12 - 20 9 - 13 • When using the long shank type, the depth of cut, pick

Hardened steels (1) 230 ~ 360 6 - 10 5 - 8 feed, cutting speed, and table feed should be reduced

Prehardened AH120 (2) to 70 %-90 % of the values shown in the tables.

steels 260 ~ 400 6 - 10 5 - 8

< A980 (3) 160 ~ 300 3 - 6 2 - 5

: Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–125

pages (14-1)