Page 715 - Tungaloy Catalog

P. 715

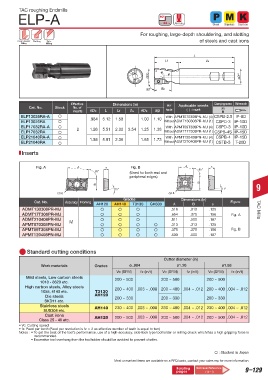

TAC roughing Endmills

ELP-A 90° Air Hole Steel Stainless Cast Iron

~ 44 in

For roughing, large-depth shouldering, and slotting

Deep Shoulder Slotting Side of steels and cast irons

Milling Milling

L

Lf R s

øDc øD h6

90˚ ap

Effective Dimensions (in) Air Applicable inserts Clamping screw Wrench

Cat. No. Stock No. of

inserts øDc L Lf R s øDs ap hole ( ) : insert

ELP13025RA-A .984 5.12 1.58 1.00 1.10 With APMT070308PN-MJ (4) CSPB-2.5 IP-8D

ELP13025RA Without ADMT130308PR-MJ (1) CSPD-3 IP-10D

ELP17032RA-A 2 1.26 5.51 2.00 3.54 1.25 1.38 With APMT09T308PN-MJ (4) CSPD-3 IP-10D

ELP17032RA Without ADMT17T308PR-MJ (1) CSPB-4S IP-15D

ELP21040RA-A 1.58 5.91 2.36 1.65 1.73 With APMT120408PN-MJ (4) CSPB-4 IP-15D

ELP21040RA Without ADMT210408PR-MJ (1) CSTB-5 T-20D

Inserts

Fig. A A s Fig. B A s

85° (Used for both end and 85°

peripheral edges)

B

B 9

15° 11°

r ε 0.8 r ε 0.8

Grades Dimensions (in)

Cat. No. Accuracy Honing AH120 AH140 T3130 GH330 A B s Figure

ADMT130308PR-MJ .516 .313 .125 TAC Mills

ADMT17T308PR-MJ .654 .375 .156 Fig. A

ADMT210408PR-MJ M .811 .500 .187

APMT070308PN-MJ .313 .313 .125

APMT09T308PN-MJ .375 .375 .156 Fig. B

APMT120408PN-MJ .500 .500 .187

Standard cutting conditions

Cutter diameter (in)

Work materials Grades ø..984 ø1.26 ø1.58

Vc (SFM) fz (in/t) Vc (SFM) fz (in/t) Vc (SFM) fz (in/t)

Mild steels, Low carbon steels 200 ~ 500 200 ~ 500 200 ~ 500

1018 - 8620 etc.

High carbon steels, Alloy steels 200 ~ 400 .003 ~ .008 200 ~ 400 .004 ~ .012 200 ~ 400 .004 ~ .012

1055, 4140 etc. T3130

Die steels AH120 200 ~ 330 200 ~ 330 200 ~ 330

SKD11 etc.

Stainless steels AH140 230 ~ 400 .003 ~ .008 230 ~ 400 .004 ~ .012 230 ~ 400 .004 ~ .012

SUS304 etc.

Cast irons 200 ~ 500 .003 ~ .008 200 ~ 500 .004 ~ .012 200 ~ 500 .004 ~ .012

Class 25 - 40 etc. AH120

• Vc: Cutting speed

• fz: Feed per tooth (Feed per revolution is fz 2 as effective number of teeth is equal to two)

Notes : • To get the best of the tool’s performance, use of a high-accuracy, side-lock type toolholder or milling chuck which has a high gripping force is

recommended.

• Excessive tool overhang from the toolholder should be avoided to prevent chatter.

: Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–129

pages (14-1)