Page 713 - Tungaloy Catalog

P. 713

TAC ball Endmills

TBN1000 ~ 15 in Cast Iron Steel

R

For medium to finish engraving of steel and

cast iron dies

Pocketing Ramping Profiling

Lf Lf Lf

øDc øDs h6 øDc øDs h6 øDc øDs h6

r ε ap R s r ε ap R s r ε ap R s

L L L

Fig. A Fig. B Fig. C

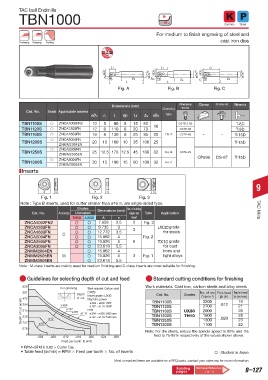

Dimensions (mm) Clamping Clamp Clamp set Wrench

Clamping screw

Cat. No. Stock Applicable inserts

øDc rε L ap Lf R s øDs Type

TBN1100S ZNCA1002FN2 10 5 90 5 15 60 16 CSTB-2.5B T-8D

TBN1120S ZNCA1203FN 12 6 110 6 20 70 CSTB-3S T-9D

TBN1160S ZNCA1603FN 16 8 130 8 25 85 20 Fig. A CSTB-4S - - T-15D

TBN1200S ZNCA2004FN 20 10 160 10 35 100 25 T-15D

ZNMM2004EN

TBN1250S ZNCA2505FN 25 12.5 175 12.5 45 100 32 Fig. B CSTA-5S

ZNMM2505EN CP536 DS-6T T-15D

TBN1300S ZNCA3005FN 30 15 190 15 90 100 32 Fig. C

ZNMM3005EN

Inserts

9

A

A s A s s

Fig. 1 Fig. 2 Fig. 3

Note : Type B inserts, used for cutter smaller than ø16 in, are single-sided type.

Grades No. of cutting TAC Mills

Cat. No. Accuracy Uncoated Dimensions (mm) edges per Type Application

TH10 UX30 A s insert

ZNCA1002FN2 7.958 2.5 2 Fig. 3

grade

ZNCA1203FN 9.735 3 3 UX30

ZNCA1603FN C 12.772 3.5 for steels

ZNCA2004FN 15.862 4 Fig. 2

grade

ZNCA2505FN 19.826 5 6 TX10

ZNCA3005FN 23.618 5.5 for cast

ZNMM2004EN 15.862 4 irons and

ZNMM2505EN M 19.826 5 3 Fig. 1 light alloys

ZNMM3005EN 23.618 5.5

Note : M-class inserts are mainly used for medium finishing and C-class inserts are most suitable for finishing.

Guidelines for selecting depth of cut and feed Standard cutting conditions for finishing

.629 For grooving Work material: Carbon steel Work materials: Cast iron, carbon steels and alloy steels

.551 (1055) No. of rev. Pick feed Table feed

Depth Insert grade: UX30 TBN1100S Grades n (min ) pf (in) vf (in/min)

Cat. No.

-1

of cut

.472

Machine power

Depth of cut: ap (in) .394 ø12 ø.629 ø.787 ø.984 ø1.18 ø.394 ~ ø.629: 2000 rpm TBN1120S UX30 2700 .012 21

19

3200

ø.394 ~ ø629: 16HP

ø.787 ~ ø1.18: 50HP

26

.315

2000

RPM

TBN1160S

1600

28

TBN1200S

TH10

.236

.020

ø.787 ~ ø1.18: 1500 rpm

23

1300

TBN1250S

.157

.078 ø10 TBN1300S 1100 22

Note: For die steels, reduce the spindle speed to 80% and the

0 feed to 75-85% respectively of the values shown above.

.004 .008 .012 .016 .020 .024 .028

Feed per tooth: fz (in/t)

• RPM=SFM X 3.82 ÷ Cutter Dia.

• Table feed (in/min) = RPM Feed per tooth No. of inserts : Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–127

pages (14-1)