Page 695 - Tungaloy Catalog

P. 695

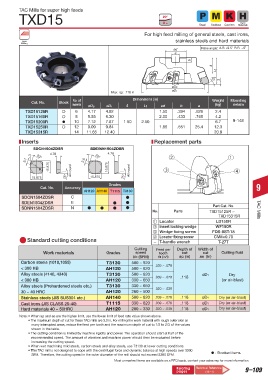

TAC Mills for super high feeds

TXD15 20° Steel Stainless Cast Iron Materials

Hard

3 in

For high feed milling of general steels, cast irons,

Face stainless steels and hard materials

Milling

ød Rake angle: A.R. +9.5˚ R.R. —5˚

a

b

R

Lf

20˚ 3

øDc

Max. ap: .118 in øD1

No. of Dimensions (in) Weight Mounting

Cat. No. Stock

inserts øDc øD1 R Lf ød b a (kg) details

TXD15125R 6 4.17 4.92 1.50 .394 .626 2.4

TXD15160R 8 5.55 6.30 2.00 .433 .748 4.2

TXD15200R 10 7.12 7.87 1.50 2.50 6.7 9-148

TXD15250R 12 9.09 9.84 1.86 .551 25.4 12.3

TXD15315R 14 11.65 12.40 20.9

Inserts Replacement parts

SDCN1504ZDSR SDE/NN1504ZDSR

4.76 4.76

20°

20° 2 1

3.7 3.0

15.875 15.875

R All round All round 3 4

15.875 15° 15.875 15°

Grades

Cat. No. Accuracy 9

AH120 AH140 T1115 T3130

SDCN1504ZDSR C

SDEN1504ZDSR E

SDNN1504ZDSR N Part Cat. No.

No. Parts TXD15125R ~ TAC Mills

TXD15315R

a Locator LD150R

b Insert locking wedge WF150R

c Wedge fixing screw FDS-8ST-18

d Locator fixing screw CM4×0.70

Standard cutting conditions - T-handle wrench T-27T

Cutting Feed per Depth of Width of

Work materials Grades speed tooth cut cut Cutting fluid

Vc (SFM) fz (in/t) ap (in) ae (in)

Carbon steels (1018,1055) T3130 500 ~ 920

< 300 HB AH120 500 ~ 820 .039 ~ .078

Alloy steels (4140, 4340) T3130 500 ~ 820 .118 øD1 Dry

< 300 HB AH120 330 ~ 650 .039 ~ .078 (or air-blast)

Alloy steels (Prehardened steels etc.) T3130 330 ~ 650

30 ~ 40 HRC AH120 260 ~ 500 .020 ~ .039

Stainless steels (JIS SUS304 etc.) AH140 500 ~ 820 .039 ~ .078 .118 øD1 Dry (or air-blast)

Cast irons (JIS CLASS 25-40) T1115 330 ~ 820 .039 ~ .078 .118 øD1 Dry (or air-blast)

Hard materials 40 ~ 50HRC AH120 200 ~ 330 .020 ~ .039 .118 øD1 Dry (or air-blast)

Note: • When ap and ae are the higher limit, use the lower limit of feed rate value shown above.

• The maximum depth of cut for these TAC mills are 3.0 in. For milling the work material with rough outer skin or

many interrupted areas, reduce the feed per tooth and the maximum depth of cut to 1/2 to 2/3 of the values

shown in the table.

• The cutting condition is limited by machine rigidity and power. The operation should start at half of the

recommended speed. The amount of vibration and machine power should then be evaluated before

increasing the cutting speed.

• When wet machining mild steels, carbon steels and alloy steels, use T3130 at lower cutting conditions.

• This TAC mill is not designed to cope with the centrifugal force and dynamic balance at high speeds over 3300

SFM. Therefore, the cutting speed in the outer diameter of the mill should not exceed 3300 SFM. : Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–109

pages (14-1)