Page 726 - Tungaloy Catalog

P. 726

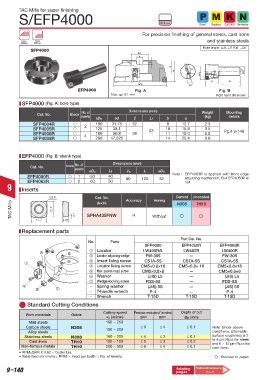

TAC Mills for super finishing

S/EFP4000 0.1 mm Steel Stainless Cast Iron Non-ferrous

For precision finishing of general steels, cast irons

Face Face and stainless steels

Milling Milling

Rake angle: A.R. +5˚ R.R. —20˚

SFP4000

ød

a

b

R

20°

Lf øDs h6

øDc

L f R s

øDc 20° L

EFP4000 Fig. A Fig. B

Max. ap: 0.1 mm Right hand (R) shown.

SFP4000 (Fig. A: bore type)

No. of Dimensions (mm) Weight Mounting

Cat. No. Stock

inserts øDc ød R Lf b a (kg) details

SFP4004R 2 100 31.75 32 8 12.7 2.3

SFP4005R 125 38.1 63 10 15.9 3.5 Pg.# 9-148

SFP4006R 4 160 50.8 38 11 19.0 5.8

SFP4008R 200 47.625 14 25.4 9.0

EFP4000 (Fig. B: shank type)

Cat. No. Stock No. of Dimensions (mm)

inserts

øDc Lf R s L øDs

EFP4050R 1 50 40 80 120 32 Note : EFP4063R is applied with front edge

adjusting mechanism. But EFP4050R is

EFP4063R 2 63 50 not.

9 Inserts

r ε 2.0 Cat. No. Accuracy Honing Cermet Uncoated

TAC Mills 12.7 H N308 TH10

(Inch)

12.7 4.76 11° SPHA435FNW Without

Replacement parts

Part Cat. No.

No. Parts

SFP4000 EFP4050R EFP4063R

a Locator LW400R/L LW402R LW400R

3 5

b Locator adjusting wedge FW-305 — FW-305

6 c Insert fixing screw CSTA-5S CSTA-5S CSTA-5S

1

d Locator fixing screw CM5×0.8×16 CM5×0.8× 16 CM5×0.8×16

e Hex. socket-head screw CM5×0.8×8 — CM5×0.8×8

f Washer (JIS) L5 — (JIS) L5

g Wedge-locking screw FDS-8S — FDS-8S

4 - Spring washer (JIS) 5S — (JIS) 5S

2 7

- T-handle wrench P-4 — P-4

- Wrench T-15D T-15D T-15D

Standard Cutting Conditions

Cutting speed Feed per revolution f (mm/rev) Depth of cut

Work materials Grade

vc (m/min) SFP EFP ap (mm)

Mild steels 180 ~ 250

Carbon steels N308 150 ~ 200 ≤ ≤ ≤ Note: Under above

6

0.1

4

Alloy steels conditions, attainable

Stainless steels N308 160 ~ 200 ≤ ≤ ≤ surface roughness is 3

0.1

3

4

5

3

0.2

Cast irons TH10 100 ~ 150 ≤ ≤ ≤ to 4 µm RzJIS for steels

and 6 ~ 12 µm RzJIS for

0.1

4

Non-ferrous metals TH10 200 ~ 500 ≤ ≤ ≤ cast irons.

6

• RPM=SFM X 3.82 ÷ Cutter Dia.

• Table feed (mm/min) = RPM Feed per tooth No. of inserts : Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–140 Relating Technical Reference

pages

(14-1)