Page 725 - Tungaloy Catalog

P. 725

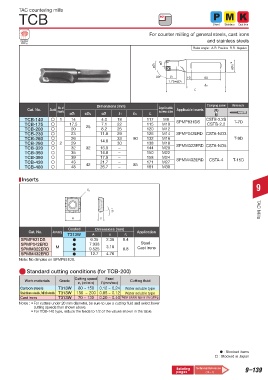

TAC countering mills

TCB 90° Steel Stainless Cast Iron

For counter milling of general steels, cast irons

Counter and stainless steels

Milling

Rake angle: A.R. Positive R.R. Negative

øD (Min.)

øD1 øDs h6

90° R 1 10 60

1.75×øD1

R s

L

No. of

Cat. No. Stock inserts Dimensions (mm) Applicable Applicable inserts Clamping screw Wrench

screw size

øD1 øDs øD R1 R s L

TCB-140 1 14 4.0 18 117 M8 SPMP831DS CSTB-2.2S T-7D

TCB-175 17.5 25 7.1 22 115 M10 CSTB-2.2

TCB-200 20 8.2 25 120 M12

TCB-230 23 11.0 29 126 M14 SPMP042ERD CSTA-NO3

TCB-260 26 33 80 132 M16 T-9D

TCB-290 2 29 14.0 30 138 M18 SPMM322ERD CSTA-NO5

TCB-320 32 32 16.9 - 144 M20

TCB-350 35 14.0 - 150 M22

TCB-390 39 17.9 - 158 M24 SPMM432ERD CSTA-4 T-15D

TCB-430 43 42 21.7 - 85 171 M27

TCB-480 48 26.7 - 181 M30

Inserts

9

r ε

11° TAC Mills

A s

Coated Dimensions (mm)

Cat. No. Accuracy Application

T313W A s rε

SPMP831DS d 6.35 2.38 0.4

SPMP042ERD d 7.938 Steel ·

SPMM322ERD M d 9.525 3.18 0.8 Cast irons

SPMM432ERD d 12.7 4.76

Note: No dimples on SPMP831DS.

Standard cutting conditions (for TCB-200)

Cutting speed Feed

Work materials Grade Cutting fluid

vc (m/min) f (mm/rev)

Carbon steels T313W 80 ~ 150 0.12 ~ 0.24 Water soluble type

Stainless steels, Mild steels T313W 150 ~ 200 0.05 ~ 0.12 Water soluble type

Cast irons T313W 70 ~ 130 0.20 ~ 0.40 Water soluble type or dry cutting

Notes : • For cutters under 20 mm diameter, be sure to use a cutting fluid and select lower

cutting speeds than shown above.

• For TCB-140 type, reduce the feeds to 1/2 of the values shown in the table.

d : Stocked items

: Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Technical Reference 9–139

pages (14-1)