Page 721 - Tungaloy Catalog

P. 721

TAC Flash Mills for plunging

TZF11

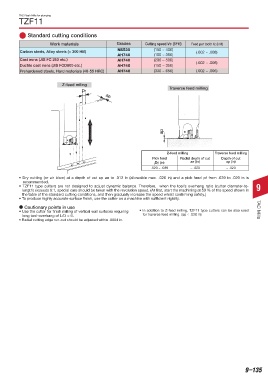

Standard cutting conditions

Work materials Grades Cutting speed Vc (SFM) Feed per tooth fz (in/t)

Carbon steels, Alloy steels (< 300 HB) NS530 (150 ~ 400) (.002 ~ .008)

AH740 (150 ~ 350)

Cast irons (JIS FC 250 etc.) AH740 (200 ~ 500)

Ductile cast irons (JIS FCD600 etc.) AH740 (150 ~ 350) (.002 ~ .008)

Prehardened steels, Hard materials (40-55 HRC) AH740 (330 ~ 650) (.002 ~ .006)

Z-feed miling

Traverse feed milling

pf

ae

ap

Z-feed milling Traverse feed milling

Pick feed Radial depth of cut Depth of cut

pf (in) ae (in) ap (in)

.020 ~ .039 ~ .020 ~ .020

• Dry cutting (or air blow) at a depth of cut up ae to .012 in (allowable max. .020 in) and a pick feed pf from .039 to .020 in is

recommended.

• TZF11 type cutters are not designed to adjust dynamic balance. Therefore, when the tool’s overhang ratio (cutter diameter-to- 9

length) exceeds 6:1, special care should be taken with the revolution speed. (At first, start the machining at 50 % of the speed shown in

the table of the standard cutting conditions, and then gradually increase the speed whilst confirming safety.)

• To produce highly accurate surface finish, use the cutter on a machine with sufficient rigidity.

Cautionary points in use

• Use the cutter for finish milling of vertical wall surfaces requiring • In addition to Z-feed milling, TZF11 type cutters can be also used TAC Mills

long tool-overhang of L/D > 6. for traverse feed milling. (ap ≤ .020 in)

• Radial cutting edge run-out should be adjusted within .0004 in.

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–135