Page 724 - Tungaloy Catalog

P. 724

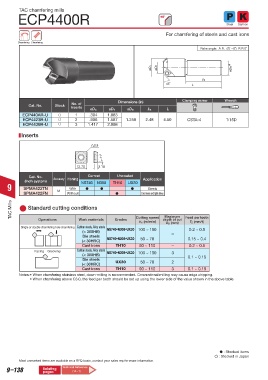

TAC chamfering mills

ECP4400R 45° Steel Cast Iron

For chamfering of steels and cast irons

Chamfering Chamfering

Rake angle: A.R. +3˚( —8˚) R.R.0˚

øD1 øDc øDs h6

R s

45˚ L

Dimensions (in) Clamping screw Wrench

No. of

Cat. No. Stock

inserts

øDc øD1 øDs R s L

ECP440AR-U 1 .394 1.083

ECP4423R-U 2 .906 1.587 1.250 2.48 4.50 CSTA-4 T-15D

ECP4436R-U 3 1.417 2.098

Inserts

r ε 0.8

11°

12.70 3.18

Cat. No. Cermet Uncoated

(Inch system) Accuracy Honing NS740 N308 TH10 UX30 Application

9 SPMA422TN With d d d Steels

SPMA422FN M Without d Cast irons and light alloys

TAC Mills Standard cutting conditions

Maximum

Cutting speed

Grades

Operations

Work materials

vc (m/min) depth of cut Feed per tooth

fz (mm/t)

ap (mm)

Single or double chamfering hole chamfering Carbon steels, Alloy steels NS740•N308•UX30 100 ~ 150 0.2 ~ 0.5

(< 300HB) -

Die steels

(< 30HRC) NS740•N308•UX30 50 ~ 70 0.15 ~ 0.4

Cast irons TH10 90 ~ 110 - 0.2 ~ 0.6

Facing Grooving Carbon steels, Alloy steels NS740•N308•UX30 100 ~ 150 3

(< 300HB) 0.1 ~ 0.15

Die steels

(< 30HRC) UX30 50 ~ 70 2

Cast irons TH10 90 ~ 110 3 0.1 ~ 0.15

Notes: • When chamfering stainless steel, down-milling is recommended. Conventional milling may cause edge chipping.

• When chamfering above C3.0, the feed per tooth should be set up using the lower side of the value shown in the above table.

d : Stocked items

: Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–138 Relating Technical Reference

(14-1)

pages