Page 784 - Tungaloy Catalog

P. 784

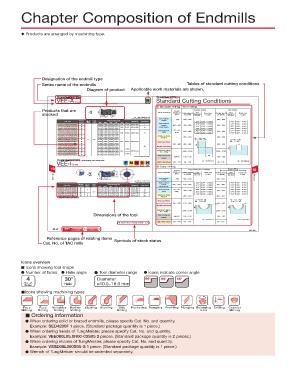

Chapter Composition of Endmills

r Products are arranged by machining type.

Designation of the endmill type

Series name of the endmills Tables of standard cutting conditions

Diagram of product Applicable work materials are shown.

Standard Cutting Conditions

VEE-A Square

Non-ferrous

● Shoulder milling / Slot milling

R

Products that are øDh6 Brinell Shoulder milling Slot milling

stocked Work materials hardness Cutting Speed diameter Feed rate Vc (SFM) øD (in) Feed rate

Tool

Tool

(HB)

Cutting Speed diameter

fz (ipt)

Vc (SFM)

fz (ipt)

øD (in)

of

L ød1 ap = Max. depth of cut of cut

S = Connection screw size Low carbon

Grade Dimensions (in) steels ~ 200 560 ~ 630 560 ~ 630

Cat. No. No. of Helix Wrench Torque (N•m) .250" 0.001 ~ 0.003 .250" 0.001 ~ 0.002

KS15F øD ød1 ap R S L

flutes

angle

VEE031L20R020AU03S05 ● 0.312 0.300 0.300 0.200 0.200 0.020 0.020 S05 0.390 KEYV-S05 7 High carbon 200 ~ 300 460 ~ 500 .312" 0.001 ~ 0.004 460 ~ 500 .312" 0.001 ~ 0.003

steels

VEE037L20R031AU03S06 ● 0.375 0.360 0.360 0.230 0.230 0.031 0.031 S06 0.510 KEYV-S06 10 Alloy steels .375" 0.001 ~ 0.004 .375" 0.002 ~ 0.004

VEE037L20R062AU03S06 ● 0.375 0.360 0.360 0.230 0.230 0.062 0.062 .500" 0.002 ~ 0.004 .500" 0.002 ~ 0.004

VEE050L31R031AU03S08 ● 0.500 0.480 0.480 0.310 0.310 0.031 0.031 Prehardened 30 ~ 40 360 ~ 430 .625" 0.002 ~ 0.005 360 ~ 430 .625" 0.002 ~ 0.005

VEE050L31R062AU03S08 ● 0.500 0.480 0.480 0.310 0.310 0.062 0.062 S08 0.650 KEYV-S08 15 steel HRC .750" 0.002 ~ 0.007 .750" 0.002 ~ 0.006

VEE050L31R094AU03S08 ● 0.500 0.480 0.480 0.310 0.310 0.094 0.094

VEE050L31R125AU03S08 ● 0.500 0.480 0.480 0.310 0.310 0.125 0.125 Stainless steels

VEE062L39R000AU03S10 ● 0.625 0.600 0.600 0.390 0.390 0.000 0.000 304,316 - 260 ~ 530 ap = 0.6 x øD 260 ~ 530

VEE062L39R031AU03S10 ● 3 45° 0.625 0.600 0.600 0.390 0.390 0.031 0.031 ae = 0.25 x øD ap = 0.5 x øD

VEE062L39R062AU03S10 ● 0.625 0.600 0.600 0.390 0.390 0.062 0.062 S10 0.810 KEYV-S10 Grey cast irons ae = 1 x øD

VEE062L39R094AU03S10 ● 0.625 0.600 0.600 0.390 0.390 0.094 0.094 150 ~ 250 430 ~ 600 430 ~ 600 ae

VEE062L39R125AU03S10 ● 0.625 0.600 0.600 0.390 0.390 0.125 0.125 28 ap

VEE075L47R062AU03S12 ● 0.750 0.720 0.720 0.470 0.470 0.062 0.062 Ductile cast irons ap

VEE075L47R094AU03S12 ● 0.750 0.720 0.720 0.470 0.470 0.094 0.094 1.000

VEE075L47R125AU03S12 ● 0.750 0.720 0.720 0.470 0.470 0.125 0.125 S12 KEYV-S12 Aluminum alloys - 2300 ~2700 2300 ~ 2700

Si < 13%)

VEE075L50R008AU03S12 ● 0.750 0.720 0.720 0.500 0.500 0.008 0.008 1.000

VEE075L50R020AU03S12 ● 0.750 0.720 0.720 0.500 0.500 0.020 0.020 High hardened ae

● For non-ferrousFor non-ferrous metals 55HRC 100 ~ 130 100 ~ 130

For

steels

Interchangable solid carbide heads øD = Tool Diameter øD = Tool Diameter

High temp alloys 150 ~ 225 60 ~ 125 60 ~ 125

VEE-I Square Steel Stainless Cast Iron Superalloys Materials ● Copy milling

Hard

10 Copy milling (for roughing) Copy milling 10

C α1 α2 Brinell (for semi-finishing and finishing)

Tool

Work materials hardness Cutting Speed diameter Feed rate Cutting Speed diameter Feed rate

Tool

øDe8

(HB)

Endmills α2 α1 Low carbon Vc (SFM) øD (in) fz (ipt) Vc (SFM) øD (in) fz (ipt) Endmills

R, C

ap = Max. depth of cut of cut of steels ~ 200 560 ~ 630 560 ~ 630

α1 = = α2 S = Connection screw size

High carbon .250" 0.001 ~ 0.003 .250" 0.001 ~ 0.003

Grade No. of Helix Dimensions (in) steels 200 ~ 300 460 ~ 500 460 ~ 500

Cat. No. flutes angle Wrench Torque (N•m) .312" 0.001 ~ 0.004 .312" 0.001 ~ 0.004

AH725 øD ød1 ap C S L Alloy steels

VEE031L20C010IU04S05 ● 0.312 0.300 0.300 0.200 0.200 0.010 0.010 S05 0.390 KEYV-S05 7 .375" 0.001 ~ 0.004 .375" 0.002 ~ 0.004

VEE037L27C016IU04S06 ● 4 0.375 0.370 0.370 0.270 0.270 0.016 0.016 S06 0.510 KEYV-S06 10 Prehardened 30 ~ 40 360 ~ 430 .500" 0.002 ~ 0.004 360 ~ 430 .500" 0.002 ~ 0.004

VEE050L37C014IU04S08 ● 38° 0.500 0.480 0.480 0.370 0.370 0.014 0.014 S08 0.650 KEYV-S08 15 steel HRC .625" 0.002 ~ 0.005 .625" 0.002 ~ 0.005

VEE062L47C016IU05S10 ● 5 0.625 0.600 0.600 0.470 0.470 0.016 0.016 S10 0.810 KEYV-S10 28 .750" 0.002 ~ 0.007 .750" 0.002 ~ 0.007

VEE075L62C016IU06S12 ● 6 0.750 0.720 0.720 0.620 0.620 0.016 0.016 S12 1.000 KEYV-S12 28 Stainless steels - 260 ~ 530 260 ~ 530

● Chamfered corner style endmills 304,316

ap = 0.3 x øD ap = 0.1 x øD

Grey cast irons ae = 0.4 x øD ae = 0.1 x øD

150 ~ 250 430 ~ 600 ae 430 ~ 600 ae

Ductile cast irons

ap ap

Aluminum alloys

Si < 13%) - 2300 ~2700 2300 ~2700

Dimensions of the tool High hardened 55HRC 100 ~ 130 100 ~ 130

steels

øD = Tool Diameter øD = Tool Diameter

High temp alloys 150 ~ 225 60 ~ 125 60 ~ 125

: Stocked items / Package / Package / Quantity = 2 pcs.

10–88 Relating Cutting Conditions Technical reference 10–23

– –

pages

(14-1)

(10-23)

Reference pages of relating items

Cat. No. of TAC mills Symbols of stock status

Icons overview

j Icons showing tool shape

d Number of flutes d Helix angle d Tool diameter range d Icons indicate corner angle

4 30° Diameter 86° 65° 45°

No. of ø10.0~16.0 mm

flutes Helix

nIcons showing machining types

R R R

Face Face Shoulder Radius Slotting Slotting Side Pocketing Ramping Profiling Plunging Enlarging Drilling Counter

Milling Milling Milling Milling Milling Hole Milling

j Ordering information

d When ordering solid or brazed endmills, please specify Cat. No. and quantity.

Example: SED4200F 1 piece. (Standard package quantity is 1 piece.)

d When ordering heads of TungMeister, please specify Cat. No. and quantity.

Example: VEE080L05.0R00-03S05 2 pieces. (Standard package quantity is 2 pieces.)

d When ordering shanks of TungMeister, please specify Cat. No. and quantity.

Example: VSSD08L060S05-S 1 piece. (Standard package quantity is 1 piece.)

d Wrench of TungMeister should be orderded separately.