Page 787 - Tungaloy Catalog

P. 787

Features

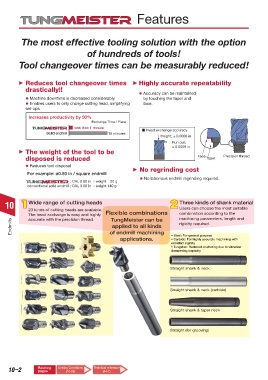

The most effective tooling solution with the option

of hundreds of tools!

Tool changeover times can be measurably reduced!

c Reduces tool changeover times c Highly accurate repeatability

drastically!!

l Accuracy can be maintained

l Machine downtime is decreased considerably. by touching the taper and

l Enables users to only change cutting head, simplifying face.

set-ups

Increases productivity by 90%

Exchange Time / Piece

less than 1 minute ■ Head exchange accuracy

Solid endmill 10 minutes

Height: ± 0.0008 in

Run out:

≤ 0.0008 in

c The weight of the tool to be

disposed is reduced Face Taper Precision thread

l Reduces tool disposal c No regrinding cost

For example: ø0.50 in / square endmill

l No laborious endmill regrinding required.

: OAL 0.80 in weight 20 g

conventional solid endmill : OAL 3.00 in weight 140 g

10 1 Wide range of cutting heads 2 Three kinds of shank material

23 kinds of cutting heads are available. Flexible combinations Users can choose the most suitable

The head exchange is easy and highly TungMeister can be combination according to the

machining parameters, length and

accurate with the precision thread.

Endmills of endmill machining rigidity required.

applied to all kinds

applications. • Steel: For general purpose

• Carbide: For highly accurate machining with

excellent rigidity

• Tungsten: Reduced chattering due to vibration

dampening capacity

Straight shank & neck

Straight shank & neck (carbide)

Straight shank & taper neck

Straight (for grooving)

10–2 Relating Cutting Conditions Technical reference

pages

(10-23)

(14-1)