Page 839 - Tungaloy Catalog

P. 839

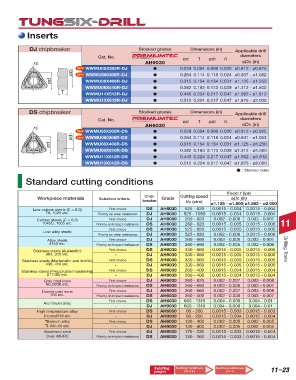

Inserts

DJ chipbreaker Stocked grades Dimensions (in) Applicable drill

Cat. No. TUNGAL O Y ød T ød1 rε diameters

r ε AH9030 øDc (in)

NEW WWMU05X205R-DJ d 0.228 0.094 0.098 0.020 ø0.812 - ø0.875

ød1 NEW WWMU060306R-DJ d 0.264 0.114 0.118 0.024 ø0.937 - ø1.062

ød WWMU08X408R-DJ d 0.315 0.154 0.134 0.031 ø1.125 - ø1.250

WWMU09X510R-DJ d 0.382 0.193 0.173 0.039 ø1.312 - ø1.500

T WWMU11X512R-DJ d 0.445 0.224 0.217 0.047 ø1.562 - ø1.812

WWMU13X512R-DJ d 0.512 0.224 0.217 0.047 ø1.875 - ø2.000

DS chipbreaker Stocked grades Dimensions (in) Applicable drill

Cat. No. TUNGAL O Y ød T ød1 rε diameters

AH6030 øDc (in)

r ε

NEW WWMU05X205R-DS d 0.228 0.094 0.098 0.020 ø0.812 - ø0.925

ød1 NEW WWMU060306R-DS d 0.264 0.114 0.118 0.024 ø0.941 - ø1.063

ød WWMU08X408R-DS d 0.315 0.154 0.134 0.031 ø1.125 - ø1.250

WWMU09X510R-DS d 0.382 0.193 0.173 0.039 ø1.312 - ø1.500

T WWMU11X512R-DS d 0.445 0.224 0.217 0.047 ø1.562 - ø1.812

WWMU13X512R-DS d 0.512 0.224 0.217 0.047 ø1.875 - ø2.000

d : Stocked items

Standard cutting conditions

Feed: f (ipr)

Workpiece materials Selection criteria Chip- Grade Cutting speed øDc (in)

breaker Vc (sfm) ø1.125 - ø1.500 ø1.562 - ø2.000

Low carbon steels (C < 0.3) First choice DS AH6030 525 - 820 0.0015 - 0.004 0.0015 - 0.004

70, 1025 etc. Priority on wear resistance DJ AH9030 525 - 1050 0.0015 - 0.004 0.0015 - 0.004

Carbon steels (C > 0.3) First choice DJ AH9030 260 - 820 0.002 - 0.006 0.003 - 0.007

1045C, 1055 etc. Priority on impact resistance DS AH6030 260 - 820 0.0015 - 0.005 0.0015 - 0.006 11

First choice DS AH6030 525 - 820 0.0015 - 0.005 0.0015 - 0.005

Low alloy steels

Priority on wear resistance DJ AH9030 525 - 820 0.002 - 0.006 0.0015 - 0.006

Alloy steels First choice DJ AH9030 260 - 660 0.003 - 0.006 0.003 - 0.007

4140 etc. Priority on impact resistance DS AH6030 260 - 660 0.002 - 0.005 0.002 - 0.006

Stainless steels (Austenitic) First choice DS AH6030 330 - 660 0.0015 - 0.005 0.0015 - 0.005 Drilling Tools

304, 316 etc. - DJ AH9030 330 - 660 0.0015 - 0.005 0.0015 - 0.005

Stainless steels (Martensitic and ferritic) First choice DS AH6030 330 - 660 0.0015 - 0.005 0.0015 - 0.005

430, 416 etc. - DJ AH9030 330 - 660 0.0015 - 0.005 0.0015 - 0.005

Stainless steels (Precipitation hardening) First choice DS AH6030 260 - 400 0.0015 - 0.004 0.0015 - 0.004

S17400 etc. - DJ AH9030 260 - 400 0.0015 - 0.004 0.0015 - 0.004

Gray cast irons First choice DJ AH9030 260 - 820 0.002 - 0.007 0.003 - 0.008

No.250B etc. Priority on impact resistance DS AH6030 260 - 660 0.003 - 0.006 0.003 - 0.007

Ductile cast irons First choice DJ AH9030 260 - 660 0.002 - 0.007 0.003 - 0.008

700 etc. Priority on impact resistance DS AH6030 260 - 500 0.002 - 0.006 0.003 - 0.007

First choice DS AH6030 660 - 1310 0.004 - 0.008 0.004 - 0.01

Aluminum alloy

- DJ AH9030 660 - 1310 0.004 - 0.008 0.004 - 0.01

High temperature alloy First choice DS AH6030 60 - 200 0.0015 - 0.003 0.0015 - 0.003

Inconel718 etc - DJ AH9030 60 - 200 0.0015 - 0.004 0.0015 - 0.004

Titanium alloy First choice DS AH6030 130 - 400 0.002 - 0.005 0.002 - 0.005

Ti-6Al-4V etc. - DJ AH9030 130 - 400 0.002 - 0.005 0.002 - 0.005

Hardened steel First choice DJ AH9030 170 - 330 0.0015 - 0.003 0.0015 - 0.004

Over 40HRC Priority on impact resistance DS AH6030 130 - 260 0.0015 - 0.003 0.0015 - 0.004

Relating Cutting Conditions Technical reference 11–23

pages (11-14 ) (14-1)