Page 161 - All Industrial Tool Supply | General Catalog

P. 161

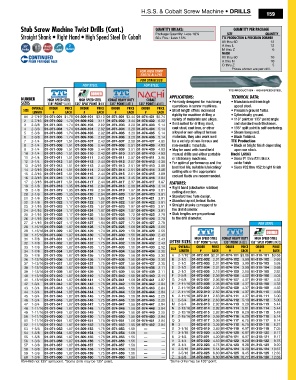

H.S.S. & Cobalt Screw Machine • DRILLS

159

Stub Screw Machine Twist Drills (Cont.) QuanTiTy BreakS: QuanTiTy Per PaCkage

Straight Shank • Right Hand • High Speed Steel Or Cobalt Package Quantity: Less 10% Size QuanTiTy

TTC ProDuCTion & PreCiSion DorMer

60+ Pcs.: Less 15%

#1 thru 60 12

A thru L 12

M thru Z 6

naChi

#1 thru 60 10

A thru N 10

O thru Z 5

Prices shown are per drill.

FOR HIGH TEMP

EXOTIC ALLOYS

FOR STAINLESS

FOR STEEL FOR STEEL

TTC ProduCTion - HigH sPeed sTeel

nuMBer high SPeeD STeel high SPeeD STeel CoBalT heavy DuTy CoBalT APPLICATIONS: TeChNICAL DATA:

SizeS 118° PoinT* [A14] 135° SPliT PoinT [R41C] 135° PoinT [A131] 135° PoinT [L6563] • Primarily designed for machining • Manufactured from high

overall orDer PriCe orDer PriCe orDer PriCe orDer PriCe operations in screw machines. speed steel.

Size • Short length offers increased • Precision ground flutes.

lengTh # eaCh # eaCh # eaCh # eaCh

#1 2-7/16" 01-071-001 $1.79 01-309-101 $3.10 01-074-001 $3.44 01-074-401 $5.74 rigidity for machine drilling a • Cylindrically ground.

2 2-7/16 01-071-002 1.79 01-309-102 3.11 01-074-002 3.44 01-074-402 6.32 variety of materials and alloys. • 118° point or 135° point angle

3 2-3/8 01-071-003 1.74 01-309-103 2.92 01-074-003 3.20 01-074-403 5.14 • Best suited for drilling steel, and standard web thickness.

4 2-3/8 01-071-004 1.74 01-309-104 2.92 01-074-004 3.20 01-074-404 5.14 cast steel, cast iron, or other • 135° split point is self-centering.

5 2-3/8 01-071-005 1.74 01-309-105 2.92 01-074-005 3.20 01-074-405 5.14 alloyed or non-alloyed ferrous • Steam tempered.

6 2-3/8 01-071-006 1.74 01-309-106 2.92 01-074-006 3.20 01-074-406 5.14 materials, they also work well • Black finished.

7 2-1/4 01-071-007 1.51 01-309-107 2.43 01-074-007 2.58 01-074-407 4.05 for a variety of non-ferrous and TTC Production

8 2-1/4 01-071-008 1.51 01-309-108 2.44 01-074-008 2.51 01-074-408 4.03 non-metallic materials. • Black or bright finish depending

9 2-1/4 01-071-009 1.51 01-309-109 2.44 01-074-009 2.51 01-074-409 4.03 • May be used with hand held upon our stock.

10 2-1/4 01-071-010 1.51 01-309-110 2.43 01-074-010 2.51 01-074-410 4.03 manual drills and either portable Nachi L6563

11 2-1/4 01-071-011 1.51 01-309-111 2.43 01-074-011 2.57 01-074-411 3.96 or stationary machines. • Sizes #1 thru #31: black

12 2-1/4 01-071-012 1.51 01-309-112 2.44 01-074-012 2.57 01-074-412 4.35 • For optimal performance and the oxide finish

13 2-3/16 01-071-013 1.51 01-309-113 2.44 01-074-013 2.51 01-074-413 3.88 best tool life, suitable lubricating/ • Sizes #32 thru #52: bright finish

14 2-3/16 01-071-014 1.51 01-309-114 2.44 01-074-014 2.51 01-074-414 3.88 cutting oils or the appropriate

15 2-3/16 01-071-015 1.51 01-309-115 2.44 01-074-015 2.51 01-074-415 3.88 coolant fluids are recommended.

16 2-3/16 01-071-016 1.51 01-309-116 2.44 01-074-016 2.45 01-074-416 3.84

17 2-3/16 01-071-017 1.51 01-309-117 2.44 01-074-017 2.37 01-074-417 3.67 FeATureS:

18 2-1/8 01-071-018 1.35 01-309-118 2.04 01-074-018 2.06 01-074-418 3.14 • Right hand (clockwise rotation)

19 2-1/8 01-071-019 1.35 01-309-119 2.04 01-074-019 1.97 01-074-419 3.01 cutting direction.

20 2-1/8 01-071-020 1.35 01-309-120 2.04 01-074-020 1.97 01-074-420 3.01 • Standard two flute design.

21 2-1/8 01-071-021 1.17 01-309-121 1.96 01-074-021 1.94 01-074-421 3.01

22 2-1/8 01-071-022 1.17 01-309-122 1.97 01-074-022 1.97 01-074-422 3.01 • Standard spiral, helical flutes.

23 2-1/16 01-071-023 1.17 01-309-123 1.97 01-074-023 1.97 01-074-423 3.01 • Straight shanks correspond to

24 2-1/16 01-071-024 1.17 01-309-124 1.97 01-074-024 1.97 01-074-424 3.01 the drill diameter.

25 2-1/16 01-071-025 1.17 01-309-125 1.94 01-074-025 1.72 01-074-425 2.79 • Stub lengths are proportional

26 2-1/16 01-071-026 1.17 01-309-126 1.94 01-074-026 1.72 01-074-426 2.79 to the drill diameter.

27 2-1/16 01-071-027 1.17 01-309-127 1.94 01-074-027 1.73 01-074-427 2.79 FOR STEEL

28 1-15/16 01-071-028 1.07 01-309-128 1.75 01-074-028 1.56 01-074-428 2.55

29 1-15/16 01-071-029 1.07 01-309-129 1.74 01-074-029 1.56 01-074-429 2.55

30 1-15/16 01-071-030 1.07 01-309-130 1.74 01-074-030 1.56 01-074-430 2.43

31 1-7/8 01-071-031 1.07 01-309-131 1.74 01-074-031 1.56 01-074-431 2.43 high SPeeD STeel CoBalT heavy DuTy high SPeeD STeel

32 1-7/8 01-071-032 1.07 01-309-132 1.75 01-074-032 1.56 01-074-432 2.43 leTTer SizeS 118° PoinT* [A14A] 135° PoinT [A132] 135° SPliT PoinT [R42C]

33 1-7/8 01-071-033 1.07 01-309-133 1.75 01-074-033 1.56 01-074-433 2.52 Size overall orDer PriCe orDer PriCe orDer PriCe

34 1-7/8 01-071-034 1.07 01-309-134 1.75 01-074-034 1.56 01-074-434 2.30 lengTh # eaCh # eaCh # eaCh

35 1-7/8 01-071-035 1.07 01-309-135 1.75 01-074-035 1.56 01-074-435 2.30 A 2-7/16" 01-072-001 $2.01 01-074-101 $3.66 01-310-101 $3.68

36 1-13/16 01-071-036 1.07 01-309-136 1.74 01-074-036 1.56 01-074-436 2.30 B 2-1/2 01-072-002 2.01 01-074-102 3.90 01-310-102 3.68

37 1-13/16 01-071-037 1.07 01-309-137 1.75 01-074-037 1.56 01-074-437 2.30 C 2-1/2 01-072-003 2.01 01-074-103 3.90 01-310-103 3.68

38 1-13/16 01-071-038 1.07 01-309-138 1.75 01-074-038 1.56 01-074-438 2.11 D 2-1/2 01-072-004 2.01 01-074-104 3.90 01-310-104 3.68

39 1-13/16 01-071-039 1.07 01-309-139 1.75 01-074-039 1.56 01-074-439 2.11 E 2-1/2 01-072-005 2.18 01-074-105 2.68 01-310-105 3.92

40 1-13/16 01-071-040 1.07 01-309-140 1.74 01-074-040 1.56 01-074-440 2.11 F 2-5/8 01-072-006 2.36 01-074-106 4.02 01-310-106 4.04

41 1-13/16 01-071-041 1.07 01-309-141 1.75 01-074-041 1.56 01-074-441 2.07 G 2-5/8 01-072-007 2.36 01-074-107 4.07 01-310-107 4.32

42 1-3/4 01-071-042 1.07 01-309-142 1.75 01-074-042 1.56 01-074-442 2.04 H 2-11/16 01-072-008 2.36 01-074-108 4.37 01-310-108 4.32

43 1-3/4 01-071-043 1.07 01-309-143 1.75 01-074-043 1.56 01-074-443 2.04 I 2-11/16 01-072-009 2.36 01-074-109 4.37 01-310-109 4.32

44 1-3/4 01-071-044 1.07 01-309-144 1.75 01-074-044 1.56 01-074-444 2.04 J 2-11/16 01-072-010 2.52 01-074-110 4.37 01-310-110 4.63

45 1-3/4 01-071-045 1.07 01-309-145 1.75 01-074-045 1.56 01-074-445 2.25 K 2-11/16 01-072-011 2.63 01-074-111 4.37 01-310-111 5.00

46 1-3/4 01-071-046 1.07 01-309-146 1.75 01-074-046 1.56 01-074-446 2.25 L 2-3/4 01-072-012 2.63 01-074-112 5.18 01-310-112 5.00

47 1-3/4 01-071-047 1.07 01-309-147 1.75 01-074-047 1.56 01-074-447 2.04 M 2-3/4 01-072-013 2.92 01-074-113 5.29 01-310-113 5.44

48 1-11/16 01-071-048 1.07 01-309-148 1.75 01-074-048 1.56 01-074-448 2.04 N 2-13/16 01-072-014 2.92 01-074-114 5.61 01-310-114 5.44

49 1-11/16 01-071-049 1.07 01-309-149 1.75 01-074-049 1.56 01-074-449 2.25 O 2-15/16 01-072-015 2.92 01-074-115 6.20 01-310-115 5.49

50 1-11/16 01-071-050 1.07 01-309-150 1.75 01-074-050 1.56 01-074-450 2.04 P 2-15/16 01-072-016 3.36 01-074-116 6.20 01-310-116 6.14

51 1-11/16 01-071-051 1.07 01-309-151 1.75 01-074-051 1.56 01-074-451 2.04 Q 3 01-072-017 3.36 01-074-117 6.75 01-310-117 6.14

52 1-11/16 01-071-052 1.07 01-309-152 1.75 01-074-052 1.56 01-074-452 2.04 R 3 01-072-018 3.36 01-074-118 6.75 01-310-118 6.21

53 1-5/8 01-071-053 1.07 01-309-153 1.75 01-074-053 1.56 — — S 3-1/16 01-072-019 3.69 01-074-119 6.97 01-310-119 7.05

54 1-5/8 01-071-054 1.07 01-309-154 1.75 01-074-054 1.56 — — T 3-1/16 01-072-020 4.30 01-074-120 6.97 01-310-120 8.17

55 1-5/8 01-071-055 1.07 01-309-155 1.75 01-074-055 1.56 — — U 3-1/8 01-072-021 4.30 01-074-121 6.97 01-310-121 8.17

56 1-3/8 01-071-056 1.07 01-309-156 1.75 01-074-056 1.56 — — V 3-1/4 01-072-022 4.53 01-074-122 9.28 01-310-122 8.78

57 1-3/8 01-071-057 1.07 01-309-157 1.75 01-074-057 1.56 — — W 3-1/4 01-072-023 4.75 01-074-123 9.28 01-310-123 9.20

58 1-3/8 01-071-058 1.07 01-309-158 1.75 01-074-058 1.56 — — X 3-5/16 01-072-024 5.54 01-074-124 9.28 01-310-124 10.67

59 1-3/8 01-071-059 1.07 01-309-159 1.75 01-074-059 1.56 — — Y 3-5/16 01-072-025 6.60 01-074-125 9.45 01-310-125 12.63

60 1-3/8 01-071-060 1.07 01-309-160 1.75 01-074-060 1.56 — — Z 3-3/8 01-072-026 6.60 01-074-126 10.77 01-310-126 12.63

#54-#60 not 135° split point. *Some drills may be 135° point. *Some drills may be 135° point.