Page 838 - Ceratizit Catalog

P. 838

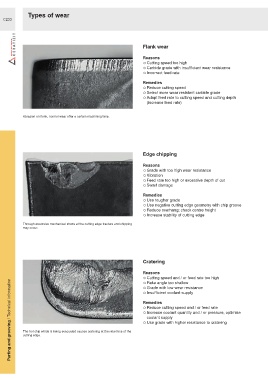

Types of wear

C233

Flank wear

Reasons

○ Cutting speed too high

○ Carbide grade with insufficient wear resistance

○ Incorrect feed rate

Remedies

○ Reduce cutting speed

○ Select more wear resistant carbide grade

○ Adapt feed rate to cutting speed and cutting depth

(increase feed rate)

Abrasion on flank, normal wear after a certain machining time.

Edge chipping

Reasons

○ Grade with too high wear resistance

○ Vibration

○ Feed rate too high or excessive depth of cut

○ Swarf damage

Remedies

○ Use tougher grade

○ Use negative cutting edge geometry with chip groove

○ Reduce overhang; check centre height

○ Increase stability of cutting edge

Through excessive mechanical stress at the cutting edge fracture and chipping

may occur.

Cratering

Reasons

○ Cutting speed and / or feed rate too high

Parting and grooving / Technical information

○ Rake angle too shallow

○ Grade with low wear resistance

○ Insufficient coolant supply

Remedies

○ Reduce cutting speed and / or feed rate

○ Increase coolant quantity and / or pressure, optimise

coolant supply

○ Use grade with higher resistance to cratering

The hot chip which is being evacuated causes cratering at the rake face of the

cutting edge.