Page 170 - Parlec Catalog

P. 170

Evolution Angle Heads

168 Stop-Block Mounting Example

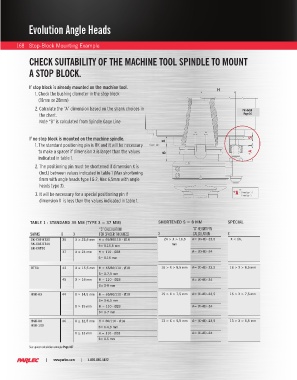

CHECK SUITABILITY OF THE MACHINE TOOL SPINDLE TO MOUNT

A STOP BLOCK.

If stop block is already mounted on the machine tool. H

1. Check the bushing diameter in the stop block

(18mm or 28mm)

2. Calculate the “A” dimension based on the shank choices in Pin detail

the chart. Page 54

Note “B” is calculated from Spindle Gage Line

= =

If no stop block is mounted on the machine spindle. X S

1. The standard positioning pin is OK and it will be necessary Gauge Line 1

to make a spacer if dimension X is larger than the values B *A

indicated in table 1.

2. The positioning pin must be shortened if dimension X is

(Incl.) between values indicated in table 1 (Max shortening

8mm with angle heads type 1 & 2, Max 6,5mm with angle

heads type 3).

Pin

3. It will be necessary for a special positioning pin if *A - 35mm Type1-2

- 37mm Type 3

dimension X is less than the values indicated in table 1.

TABLE 1 - STANDARD 35 MM (TYPE 3 = 37 MM) SHORTENED S = 8 MM SPECIAL

“S” CALCULATION “A” HEIGHT PIN

SHANKS B X FOR SPACER THICKNESS X CALCULATION X

SK-CAT-BT30 35 X ≥ 23,5 mm H = 65/80/110 - Ø18 24 > X > 16,5 A= (X+B) -23,5 X < 16,

SK-CAT-BT40 S= X-15,5 mm mm

SK-CAT50

37 X ≥ 24 mm H = 110 - Ø28 A= (X+B) -24

S= X-16 mm

BT50 43 X ≥ 15,5 mm H = 65/80/110 - Ø18 16 > X > 8,5 mm A= (X+B) -23,5 16 > X > 8,5 mm

S= X-7,5 mm

45 X ≥ 16 mm H = 110 - Ø28 A= (X+B) -24

S= X-8 mm

HSK-63 44 X ≥ 14,5 mm H = 65/80/110 - Ø18 15 > X > 7,5 mm A= (X+B) -23,5 15 > X > 7,5 mm

S= X-6,5 mm

X ≥ 15 mm H = 110 - Ø28 A= (X+B) -24

S= X-7 mm

HSK-80 46 X ≥ 12,5 mm H = 80/110 - Ø18 13 > X > 5,5 mm A= (X+B) -23,5 13 > X > 5,5 mm

HSK-100

S= X-4,5 mm

X ≥ 13 mm H = 110 - Ø28 A= (X+B) -24

S= X-5 mm

See spacer calculation example Page 187

| www.parlec.com | 1-800-866-5872