Page 213 - Parlec Catalog

P. 213

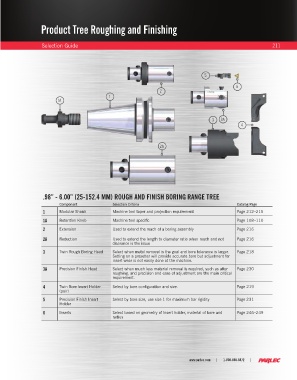

Product Tree Roughing and Finishing

Selection Guide 211

5

6

2

1

1A

3 3A

4

2A

.98” - 6.00” (25-152.4 MM) ROUGH AND FINISH BORING RANGE TREE

Component Selection Criteria Catalog Page

1 Modular Shank Machine tool taper and projection requirement Page 212–215

1A Retention Knob Machine tool specific Page 108–110

2 Extension Used to extend the reach of a boring assembly Page 216

2A Reduction Used to extend the length to diameter ratio when reach and not Page 216

clearance is the issue

3 Twin Rough Boring Head Select when metal removal is the goal and bore tolerance is larger. Page 218

Setting on a presetter will provide accurate bore but adjustment for

insert wear is not easily done at the machine.

3A Precision Finish Head Select when much less material removal is required, such as after Page 230

roughing, and precision and ease of adjustment are the main critical

requirement.

4 Twin Bore Insert Holder Select by bore configuration and size. Page 219

(pair)

5 Precision Finish Insert Select by bore size, use size 1 for maximum bar rigidity Page 231

Holder

6 Inserts Select based on geometry of insert holder, material of bore and Page 246–249

radius

www.parlec.com | 1-800-866-5872 |