Page 675 - Tungaloy Catalog

P. 675

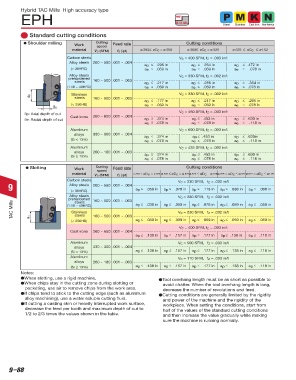

Hybrid TAC Mills High accuracy type

EPH 90° Steel Stainless Cast Iron Non-ferrous

10, 12, .630 in

Standard cutting conditions

d Shoulder milling Cutting Feed rate Cutting conditions

Work speed

≤

≤

≤

≤

material Vc (SFM) fz (ipt) ø.393 øDc < ø.500 ø.500 øDc < ø.625 ø.625 øDc ø1.02

Carbon steels Vc = 400 SFM, fz = .003 in/t

Alloy steels 200 ~ 590 .001 ~ .004

≤

ap .295 in ap .354 in ap .472 in

≤

≤

≤

≤

≤

(< 30HRC) ae .059 in ae .059 in ae .078 in

Alloy steels Vc = 330 SFM, fz = .002 in/t

prehardened

steels 160 ~ 500 .001 ~ .003 ap .217 in ap .256 in ap .354 in

≤

≤

≤

≤

≤

≤

(1.18 ~ 40HRC) ae .059 in ae .059 in ae .078 in

Stainless Vc = 330 SFM, fz = .002 in/t

ap steels 160 ~ 500 .001 ~ .003

≤

≤

≤

ap .177 in ap .217 in ap .295 in

≤

(< 250HB) ae .059 in ae .059 in ae .078 in

≤

≤

ae

ap: Axial depth of cut Vc = 460 SFM, fz = .003 in/t

Cast irons 260 ~ 650 .001 ~ .004

≤

≤

≤

ae: Radial depth of cut ap .374 in ap .453 in ap .630 in

≤

ae .078 in ae .078 in ae .118 in

≤

≤

Aluminum Vc = 660 SFM, fz = .003 in/t

alloys 330 ~ 300 .001 ~ .004 ap .374 in ap .453 in ap .630in

≤

≤

≤

(Si < 13%) ae .078 in ae .078 in ae .118 in

≤

≤

≤

Aluminum Vc = 425 SFM, fz = .002 in/t

alloys 260 ~ 180 .001 ~ .003

≤

≤

≤

(Si ≥ 13%) ap .374 in ap .453 in ap .630 in

≤

≤

≤

ae .078 in ae .078 in ae .118 in

d Slotting Work Cutting Feed rate Cutting conditions

speed

≤

≤

material Vc (SFM) fz (ipt) ø.393 øDc < ø.500 ø.500 øDc < ø.625ø.625 øDc ø.709ø.709 < øDc ø.827 ø.827 < øDc ø1.09

≤

≤

≤

Carbon steels Vc = 330 SFM, fz = .002 in/t

9 Alloy steels 200 ~ 590 .001 ~ .004 ap .059 in ap .078 in ap .118 in ap .098 in ap .098 in

≤

≤

≤

≤

≤

(< 30HRC)

Alloy steels Vc = 230 SFM, fz = .002 in/t

prehardened 160 ~ 500 .001 ~ .003 ≤ ≤ ≤ ≤ ≤

TAC Mills (1.18 ~ 40HRC) ap .039 in ap .059 in ap .078 in ap .059 in ap .059 in

steels

Stainless

Vc = 230 SFM, fz = .002 in/t

steels

ap

≤

≤

≤

≤

≤

(< 250HB) 160 ~ 500 .001 ~ .003 ap .039 in ap .039 in ap .059 in ap .059 in ap .059 in

Vc = 400 SFM, fz = .003 in/t

Cast irons 260 ~ 650 .001 ~ .004

≤

≤

≤

≤

ap .138 in ap .157 in ap .177 in ap .138 in ap .118 in

≤

Aluminum Vc = 500 SFM, fz = .003 in/t

alloys 330 ~ 300 .001 ~ .004

≤

≤

≤

≤

≤

(Si < 13%) ap .138 in ap .157 in ap .177 in ap .138 in ap .118 in

Aluminum Vc = 110 SFM, fz = .003 in/t

alloys 260 ~ 180 .001 ~ .003

≤

≤

≤

≤

≤

(Si ≥ 13%) ap .138 in ap .157 in ap .177 in ap .138 in ap .118 in

Notes:

dWhen slotting, use a rigid machine. dTool overhang length must be as short as possible to

dWhen chips stay in the cutting zone during slotting or avoid chatter. When the tool overhang length is long,

pocketing, use air to remove chips from the work area. decrease the number of revolutions and feed.

dIf chips tend to stick to the cutting edge (such as aluminum dCutting conditions are generally limited by the rigidity

alloy machining), use a water soluble cutting fluid. and power of the machine and the rigidity of the

dIf cutting a casting skin or heavily interrupted work surface, workpiece. When setting the conditions, start from

decrease the feed per tooth and maximum depth of cut to half of the values of the standard cutting conditions

1/2 to 2/3 times the values shown in the table. and then increase the value gradually while making

sure the machine is running normally.

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–88