Page 676 - Tungaloy Catalog

P. 676

Hybrid TAC Mills

EPH

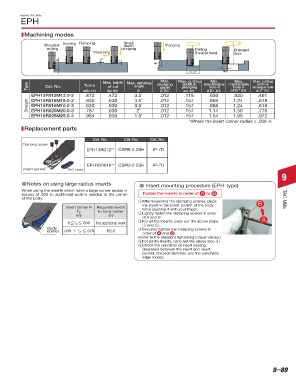

Machining modes

Shoulder Slotting Ramping Small Plunging

depth

milling plunging Drilling Enlarged

Traversing (Helical feed) hole

ap A

ae1

D1, D2 ae2

Max. depth Max. ramping Max. Max. cutting Min. Max. Max. cutting

width in

Type Cat. No. øDc (in) ap (in) angle plunging plunging machinable machinable enlarged hole

width in

Tool ø

of cut

hole ø

hole ø

depth

θ

ae2* (in)

øD2* (in)

ae1 (in)

øD1 (in)

A (in)

EPH13R012M12.0-2 .472 .472 3.5˚ .012 .118 .630 .925 .461

Straight EPH18R016M16.0-3 .630 .630 3.5˚ .012 .157 .866 1.24 .618

.630

.618

.866

1.24

3.5˚

.012

.157

.630

EPH18R016M16.0-2

1.56

2˚

.776

.630

.157

1.14

.787

.012

EPH18R020M20.0-3

1.54

.630

.012

1.95

.984

EPH18R025M25.0-4

1.5˚

.157

.972

*Where the insert corner radius ≤ .008 in

Replacement parts

Cat. No. Cat. No. Cat. No.

Clamping screw

EPH13R012** CSPB-2.2SH IP-7D

EPH18R016** CSPB-2.5SH IP-7D

(Insert pocket) TAC insert

9

dNotes on using large radius inserts d Insert mounting procedure (EPH-type)

When using the inserts which have a large corner radius in Fasten the inserts in order of A to B

excess of .039 in, additional work is needed to the corner

of the body. TAC Mills

q After loosening the clamping screws, place B

the insert in the insert pocket of the body

Insert corner R Required rework while pushing it with your finger.

r ε to body corner

(in) (in) w Lightly fasten the clamping screws in order

of A and B. A

≤

ε ≤

0 r .039 No additional work e For all the inserts, carry out the above steps

q and w.

Body r Securely tighten the clamping screws in

ε ≤

corner .039 < r .078 R2.0

order of A and B .

(Refer to the standard tightening torque values.)

t For all the inserts, carry out the above step r.

y Check the condition of insert seating,

clearance between the insert and insert

pocket, the tool diameter, and the peripheral

edge runout.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–89