Page 722 - Tungaloy Catalog

P. 722

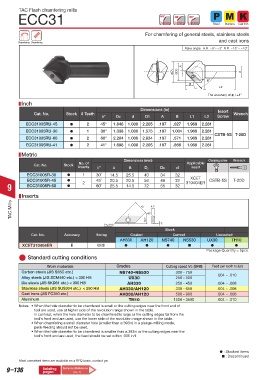

TAC Flash chamfering mills

ECC31 Chamfering Chamfering Chamfering Steel Stainless Cast Iron

60°

30°

45°

For chamfering of general steels, stainless steels

and cast irons

Chamfering Chamfering

Rake angle: A.R. —5˚~ —3˚ R.R. —15˚ ~ —10˚

A

øD1 øDc d

B

L 1 L2

The accuracy of κ : ±1°

Inch

Dimensions (in) Insert

Cat. No. Stock # Teeth Wrench

° Dc d D1 A B L1 L2 Screw

ECC31005RU-45 d 2 45° 1.846 1.000 2.205 .197 .827 1.969 2.281

ECC31005RU-30 d 1 30° 1.338 1.000 1.575 .197 1.004 1.969 2.281

CSTB-5S T-20D

ECC31005RU-60 d 2 60° 2.204 1.000 2.834 .197 .571 1.969 2.281

ECC31005RU-41 d 2 41° 1.698 1.000 2.205 .197 .866 1.969 2.281

Metric

Dimensions (mm) Clamping screw Wrench

No. of Applicable

Cat. No. Stock

inserts ° A B D 1 Dc d insert

ECC31005R-30 d 1 30˚ 14.5 25.5 40 34 32

XCET

ECC31005R-45 d 2 45˚ 20.5 20.5 56 46 32 310404ER CSTB-5S T-20D

9 ECC31005R-60 d 60˚ 25.5 14.5 72 55 32

Inserts

TAC Mills 22 45° 4.5

12.7

2-r ε .016 7°

Stock

Cat. No. Accuracy Honing Coated Cermet Uncoated

AH330 AH120 NS740 NS530 UX30 TH10

XCET310404ER E With d d d d d

Package Quantity = 5pcs.

Standard cutting conditions

Work materials Grades Cutting speed Vc (SFM) Feed per tooth fz (ipt)

Carbon steels (JIS S55C etc.) NS740•NS530 300 - 750

Alloy steels (JIS SCM440 etc.) < 300 HB UX30 250 - 500 .004 ~ .010

Die steels (JIS SKD61 etc.) < 300 HB AH330 250 - 450 .004 ~ .008

Stainless steels (JIS SUS304 etc.) < 250 HB AH330/AH120 300 - 650 .004 ~ .008

Cast irons (JIS FC250 etc.) AH330/AH120 500 - 900 .004 ~ .008

Aluminum TH10 1500 - 3500 .004 ~ .010

Notes: • When the hole diameter to be chamfered is small or the cutting edges near the front end of

tool are used, use at higher side of the revolution range shown in the table.

In contrast, when the hole diameter to be chamfered is large or the cutting edges far from the

tool's front end are used, use the lower side of the revolution range shown in the table.

• When chamfering a small diameter hole (smaller than ø.393in) in a plunge-milling mode,

peck-feeding should not be used.

• When the hole diameter to be chamfered is smaller than ø.393in or the cutting edges near the

tool's front end are used, the feed should be set within .006 in/t.

d : Stocked items

: Discontinued

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–136 Relating Technical Reference

pages

(14-1)