Page 794 - Tungaloy Catalog

P. 794

ød1

R

p

a

L

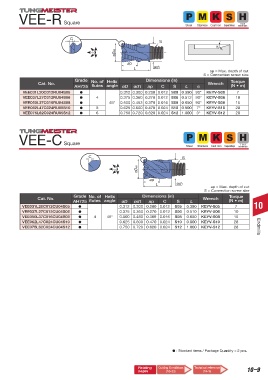

VEE-R Square øDh6 øDh6 R R a p L ød1 S S Hard

Steel Stainless Cast Iron Superalloys Materials

C

S

α

øDe9

a p

L ød1

ap = Max. depth of cut

S = Connection screw size

Grade No. of Helix Dimensions (in) Torque

Cat. No. Wrench

AH725 flutes angle øD ød1 ap C S L α (N • m)

VEE031L20C012RU04S05 ● 0.312 0.300 0.200 0.012 S05 0.390 90° KEYV-S05 7

VEE037L27C012RU04S06 ● 4 0.375 0.360 0.270 0.012 S06 0.512 90° KEYV-S06 10

VEE050L37C016RU04S08 ● 45° 0.500 0.453 0.370 0.016 S08 0.650 90° KEYV-S08 15

VEE062L47C024RU05S10 ● 5 0.625 0.600 0.470 0.024 S10 0.800 7° KEYV-S10 28

VEE075L62C024RU05S12 ● 6 0.750 0.720 0.620 0.024 S12 1.000 3° KEYV-S12 28

VEE-C Square Hard

Steel Stainless Cast Iron Superalloys Materials

C S

øDe9

● For non-ferrous metals

a p

L ød1

ap = Max. depth of cut

S = Connection screw size

Grade No. of Helix Dimensions (in) Torque

Cat. No. Wrench

AH725 flutes angle øD ød1 ap C S L (N • m)

VEE031L20C012CU04S05 ● 0.312 0.300 0.200 0.012 S05 0.390 KEYV-S05 7 10

VEE037L27C012CU04S06 ● 0.375 0.360 0.270 0.012 S06 0.510 KEYV-S06 10

VEE050L37C016CU04S08 ● 4 45° 0.500 0.480 0.369 0.016 S08 0.650 KEYV-S08 15

11.7

VEE062L47C024CU04S10 ● 0.625 0.600 0.470 0.024 S10 S 0.800 KEYV-S10 28

R

VEE075L62C024CU04S12 ● 0.750 0.720 0.620 0.024 S12 1.000 KEYV-S12 28 Endmills

øDe8

a p

L ød1

R S

øDe8

a p ød1

L

d : Stocked items / Package Quantity = 2 pcs.

R S

De8 Relating Cutting Conditions Technical reference 10–9

pages (10-23) (14-1)

a p

L ød1

R S

De8

a p

L ød1