Page 796 - Tungaloy Catalog

P. 796

C

øDe9

S

a

p

L ød1 S C øDe9 R a p L 11.7 ød1 S

øDe8

Interchangable solid carbide heads

a

4 90° p L

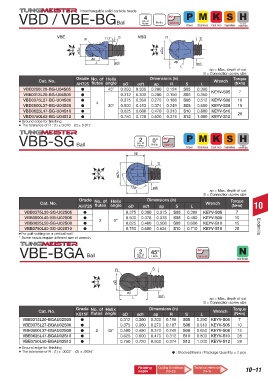

VBD / VBE-BGBall No. of Helix With R ød1 Hard

flutes

Steel Stainless Cast Iron Superalloys Materials

VBE S VBD R

R 11.7 S

øDe8 øDe8

a p

L ød1 a p ød1

L

C S ap = Max. depth of cut

S S = Connection screw size

Grade No. of Helix Dimensions (in) Torque

Cat. No. R flutes angle øD S Wrench

øDh9

AH725 øD ød1 ap R S L (N•m)

VBE0250L20-BG-U04S05 45° 0.250 0.300 0.200 0.124 S05 0.390 KEYV-S05

p

a

VBE0312L20-BG-U04S05 øDe8 ● 0.312 L p 0.200 0.156 S05 0.350 7

●

0.300

a

ød1

VBD0375L27-BG-U04S06 ● 0.375 L ød1 0.188 S06 0.512 KEYV-S06 10

0.360

0.275

VBD0500L37-BG-U04S08 ● a p 4 30° ød1 0.500 0.453 0.374 0.249 S08 0.650 KEYV-S08 15

VBD0625L47-BG-U04S10 ● L 0.625 0.600 0.470 0.313 S10 0.800 KEYV-S10

VBD0750L62-BG-U04S12 ● 0.750 0.720 0.620 0.374 S12 1.000 KEYV-S12 28

● Ground edge for finishing R S

● The tolerance of R : (1) ± 0.010 (2) ± 0.012

R 11.7 S De8

2 0° 90°

VBB-SG Ball No. of Helix With R a p ød1 Hard

flutes

øD L Steel Stainless Cast Iron Superalloys Materials

a p

a p

L ød1

R S S

De8 øDh7

R S

a p 120°

L ød1 L ød1 ap = Max. depth of cut

øD S = Connection screw size

R

Grade No. of Helix Dimensions (in) S Torque

Cat. No. Wrench

AH725 flutes angle a p øD ød1 ød1 ap S L (N•m) 10

L

De8

VBB0375L30-SG-U02S05 ● 0.375 0.300 0.315 S05 0.389 KEYV-S05 7

VBB0500L40-SG-U02S06 ● 0.500 0.378 0.378 S06 0.480 KEYV-S08 10

a

p

VBB0625L50-SG-U02S08 ● 2 0° 0.625 0.480 0.508 S08 L 0.606 KEYV-S10 15

ød1

VBB0750L60-SG-U02S10 ● 0.750 0.600 0.634 S10 0.710 KEYV-S10 28 Endmills

● For pull-cutting on a vertical wall

* Some heads require different size of wrench.

R S S

VBE-BGA Ball No. of 45° 90°

2

De8

Helix

With R

flutes

a p øDh9 Non-ferrous

L ød1

S

R a p ød1

L

øD

a p

L ød1 ap = Max. depth of cut

S = Connection screw size

Grade No. of Helix Dimensions (in) Torque

Cat. No. Wrench

KS15F flutes angle øD ød1 ap R S L (N•m)

VBE0312L20-BGAU02S05 ● 0.312 0.300 0.200 0.156 S05 0.390 KEYV-S05 7

VBE0375L27-BGAU02S06 ● 0.375 0.360 0.270 0.187 S06 0.510 KEYV-S06 10

VBE0500L37-BGAU02S08 ● 2 45° 0.500 0.480 0.370 0.249 S08 0.650 KEYV-S08 15

VBE0625L47-BGAU02S10 ● 0.625 0.600 0.470 0.312 S10 0.800 KEYV-S10 28

VBE0750L50-BGAU02S12 ● 0.750 0.720 0.500 0.374 S12 1.000 KEYV-S12 28

● Ground edge for finishing

● The tolerance of R : (1) ± .0003" (2) ± .0004" S d : Stocked items / Package Quantity = 2 pcs.

R

øD Relating Cutting Conditions Technical reference

pages (10-23) (14-1) 10–11

a p

L ød1