Page 802 - Tungaloy Catalog

P. 802

øD

W

W < 1.2 mm

øD

S

Tmax

R

W

Tmax

W

W

W < 1.0 mm

W < 1.2 mm

Interchangable solid carbide heads W R R Tmax Tmax Tmax Tmax W S S øD

4/6

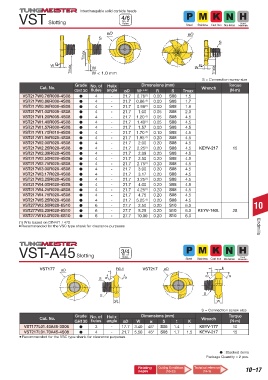

VST Slotting No. of Steel Stainless Cast Iron Non-ferrous Materials

flutes

Hard

øD øD

S

S

Tmax

W R R

Tmax W W Tmax

W < 1.0 mm

S = Connection screw size

Grade No. of Helix Dimensions (mm) Torque

Cat. No. Wrench

GH130 flutes angle øD W ± 0.02 R S Tmax (N·m)

VST217W0.76R000-4S08 ● 4 - 21.7 0.76 0.00 S08 1.5

(1)

VST217W0.86R000-4S08 ● 4 - 21.7 0.86 (1) 0.00 S08 1.7

VST217W0.96R000-4S08 ● 4 - 21.7 0.96 0.00 S08 1.9

(1)

VST217W1.00R005-4S08 ● 4 - 21.7 1.00 0.05 S08 2.0

VST217W1.20R005-4S08 ● 4 - 21.7 1.20 (1) 0.05 S08 4.5

VST217W1.40R005-4S08 ● 4 - 21.7 1.40 0.05 S08 4.5

øD

(1)

VST217W1.57R000-4S08 ● 4 - 21.7 1.57 0.00 S08 4.5

VST217W1.70R010-4S08 ● S 4 - 21.7 1.70 (1) 0.10 S08 4.5

VST217W1.95R020-4S08 ● 4 - 21.7 1.95 (1) 0.20 S08 4.5

VST217W2.00R020-4S08 ● 4 - 21.7 2.00 0.20 S08 4.5

VST217W2.25R020-4S08 ● 4 - 21.7 2.25 0.20 S08 4.5 KEYV-217 15

(1)

VST217W2.39R020-4S08 4 - 21.7 2.39 0.20 S08 4.5

R

W

VST217W2.50R020-4S08 Tmax ● 4 - 21.7 2.50 0.20 S08 4.5

●

VST217W2.75R020-4S08 ● 4 - 21.7 2.75 0.20 S08 4.5

(1)

VST217W3.00R020-4S08 ● 4 - 21.7 3.00 0.20 S08 4.5

VST217W3.17R020-4S08 ● 4 - 21.7 3.17 0.20 S08 4.5

VST217W3.25R020-4S08 ● 4 - 21.7 3.25 0.20 S08 4.5

(1)

VST217W4.00R020-4S08 ● 4 - 21.7 4.00 0.20 S08 4.5

VST217W4.25R020-4S08 ● 4 - 21.7 4.25 0.20 S08 4.5

(1)

VST217W4.75R020-4S08 ● 4 - 21.7 4.75 0.20 S08 4.5

VST217W5.25R020-4S08 ● 4 - 21.7 5.25 (1) 0.20 S08 4.5

VST277W2.50R020-6S10 ● 6 - 27.7 2.50 0.20 S10 6.0 10

VST277W5.25R020-6S10 ● 6 - 27.7 5.25 0.20 S10 6.0 KEYV-T40L 28

VST277W10.0R020-6S10 ● 6 - 27.7 10.00 0.20 S10 6.0

(1) W is based on DIN471 / 472 R0.1

● Recommended for the VSC type shank for clearance purposes øD t Endmills

S α α

3/4 S

VST-A45 Slotting No. of W Hard

flutes

Steel Stainless Cast Iron Non-ferrous Materials

VST177 øD R0.1 VST217 øD t k

t

α α

S α α

S

S

W W

S = Connection screw size

øD Grade t k Dimensions (mm)

Cat. No. No. of Helix Wrench Torque

GH130 flutes α angle øD W α S t K (N·m)

α

VST177L01.40A45-3S06 ● 3 - 17.7 3.40 45° S06 1.4 R - KEYV-177 10

VST217L01.70A45-4S08 ● 4 - 21.7 5.50 45° S08 1.7 1.5 KEYV-217 15

S W

● Recommended for the VSC type shank for clearance purposes

S

e a

W øD

d : Stocked items

Package Quantity = 2 pcs.

W

Relating Cutting Conditions Technical reference 10–17

R pages (10-23) (14-1)

S W

e a

øD

W

0.15 x 45˚

S W

e

a

øD

W

0.15 x 45˚

S W

e

a

øD

W