Page 851 - Tungaloy Catalog

P. 851

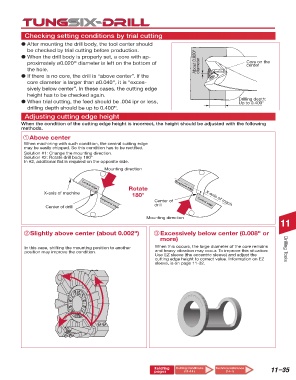

Checking setting conditions by trial cutting

d After mounting the drill body, the tool center should

be checked by trial cutting before production.

d When the drill body is properly set, a core with ap-

proximately ø0.020'' diameter is left on the bottom of About 0.020" diameter Core on the

center

the hole.

d If there is no core, the drill is “above center”. If the

core diameter is larger than ø0.040'', it is “exces-

sively below center”. In these cases, the cutting edge

height has to be checked again.

d When trial cutting, the feed should be .004 ipr or less, Drilling depth:

Up to 0.400"

drilling depth should be up to 0.400''.

Adjusting cutting edge height

When the condition of the cutting edge height is incorrect, the height should be adjusted with the following

methods.

1 Above center

When machining with such condition, the central cutting edge

may be easily chipped. So this condition has to be rectified.

Solution #1: Change the mounting direction.

Solution #2: Rotate drill body 180°

In #2, additional flat is required on the opposite side.

Mounting direction

Rotate Peripheral edge

Central edge

X-axis of machine 180°

Center of Central edge

X-axis of mach

Center of drill drill

Peripheral edge

Mounting direction

11

2 Slightly above center (about 0.002") 3 Excessively below center (0.008" or

more)

In this case, shifting the mounting position to another When this occurs, the large diameter of the core remains Drilling Tools

position may improve the condition. and heavy vibration may occur. To improve this situation:

Use EZ sleeve (the eccentric sleeve) and adjust the

cutting edge height to correct value. Information on EZ

sleeve, is on page 11-32.

Relating Cutting Conditions Technical reference 11–35

pages (11-14 ) (14-1)