Page 850 - Tungaloy Catalog

P. 850

Use of TDXU and TDSU drills

Setting of drill body is an important issue for stable machining

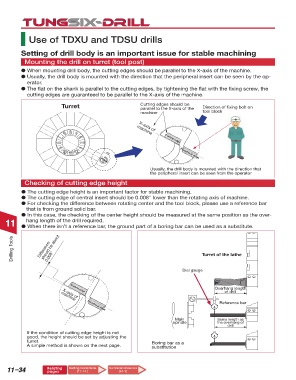

Mounting the drill on turret (tool post)

When mounting drill body, the cutting edges should be parallel to the X-axis of the machine.

Usually, the drill body is mounted with the direction that the peripheral insert can be seen by the op-

erator.

The flat on the shank is parallel to the cutting edges, by tightening the flat with the fixing screw, the

cutting edges are guaranteed to be parallel to the X-axis of the machine.

Turret Cutting edges should be Direction of fixing bolt on

parallel to the X-axis of the

machine Central edge tool block

X-axis of

machine

Peripheral edge

Usually, the drill body is mounted with the direction that

the peripheral insert can be seen from the operator

Checking of cutting edge height

The cutting edge height is an important factor for stable machining.

The cutting edge of central insert should be 0.008" lower than the rotating axis of machine.

For checking the difference between rotating center and the tool block, please use a reference bar

that is from ground solid bar.

In this case, the checking of the center height should be measured at the same position as the over-

11 When there isn’t a reference bar, the ground part of a boring bar can be used as a substitute.

hang length of the drill required.

should be about

Drilling Tools Difference: 0.008" Turret of the lathe

Dial gauge

Overhang length

of drill

Central edge

X-axis of

machine

Reference bar

Peripheral edge

Main Same length as

spindle the overhang of

drill

If the condition of cutting edge height is not

good, the height should be set by adjusting the

turret. Boring bar as a

A simple method is shown on the next page.

substitution

11–34 Relating Cutting Conditions Technical reference

pages

(11-14 )

(14-1)