Page 849 - Tungaloy Catalog

P. 849

EZ Sleeve

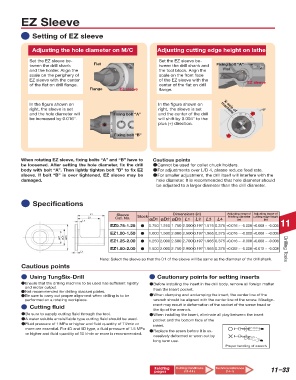

Setting of EZ sleeve

Adjusting the hole diameter on M/C Adjusting cutting edge height on lathe

Set the EZ sleeve be- Set the EZ sleeve be-

Flat Fixing bolt “A”

1.125 1.125 1.168 1.625 1.625 1.675 tween the drill shank tween the drill shank and Flat

and the holder. Align the the tool block. Align the

1.187 1.187 1.207 1.687 1.687 1.737 scale on the periphery of scale on the front face

1.250 1.250 1.258 1.750 1.750 1.778 EZ sleeve with the center of the EZ sleeve with the

EZ sleeve

of the flat on drill flange. center of the flat on drill

1.312 1.312 1.362 1.812 1.812 1.828

Flange EZ sleeve flange.

1.375 1.375 1.422 1.875 1.875 1.925

1.437 1.437 1.465 1.937 1.937 1.987

1.500 1.500 1.516 2.000 2.000 2.050 In the figure shown on In the figure shown on X-axis of

right, the sleeve is set right, the sleeve is set machine

1.562 1.562 1.637

and the hole diameter will Fixing bolt “A” and the center of the drill (+)

be increased by 0.016". will shift by 0.004" to the

plus (+) direction.

+0.4

+0.2

Fixing bolt “B” (-)

When rotating EZ sleeve, fixing bolts “A” and “B” have to Cautious points

be loosened. After setting the hole diameter, fix the drill ●Cannot be used for collet chuck holders.

body with bolt “A”. Then lightly tighten bolt ”B” to fix EZ ●For adjustments over L/D 4, please reduce feed rate.

sleeve. If bolt “B” is over tightened, EZ sleeve may be ●For smaller adjustment, the drill itself will interfere with the

damaged. hole diameter. It is recommended that hole diameter should

be adjusted to a larger diameter than the drill diameter.

Specifications

L1 Sleeve Dimensions (in) Adjusting range of Adjusting range of

L3 Cat. No. Stock finishing diameter cutting edge height

L4 øD1 øD2 øD3 L1 L2 L3 L4 (in) (in) 11

EZ0.75-1.25 ● 0.750 1.250 1.750 2.000 0.197 1.575 0.375 +0.016 ~ -0.008 +0.008 ~ -0.006

EZ1.00-1.50 ● 1.000 1.500 2.000 2.500 0.197 1.965 0.375 +0.016 ~ -0.008 +0.008 ~ -0.006

øD1 øD2 øD3

EZ1.25-2.00 ● 1.250 2.000 2.500 2.700 0.197 1.965 0.375 +0.016 ~ -0.008 +0.008 ~ -0.006

EZ1.50-2.00 ● 1.500 2.000 2.750 2.900 0.197 1.965 0.375 +0.022 ~ -0.008 +0.012 ~ -0.008 Drilling Tools

L2

Note: Select the sleeve so that the D1 of the sleeve will be same as the diameter of the drill shank.

Cautious points

Using TungSix-Drill Cautionary points for setting inserts

●Ensure that the drilling machine to be used has sufficient rigidity ●Before installing the insert in the drill body, remove all foreign matter

and motor output.

●Not recommended for drilling stacked plates. from the insert pocket.

●Be sure to carry out proper alignment when drilling is to be ●When clamping and unclamping the insert, the center line of the

performed on a rotating workpiece. wrench should be aligned with the center line of the screw. Misalign-

ment may result in deformation of the socket of the screw head or

Cutting fluid

the tip of the wrench.

●Be sure to supply cutting fluid through the tool. ●When installing the insert, eliminate all play between the insert

●A water soluble emulsifiable type cutting fluid should be used.

pocket and the bottom face of the

●Fluid pressure of 1 MPa or higher and fluid quantity of 7 l/min or

insert.

more are essential. For 4D and 5D type, a fluid pressure of 1.5 MPa

●Replace the screw before it is ex-

or higher and fluid quantity of 10 l/min or more is recommended.

cessively deformed or worn out by

long term use.

Proper handling of wrench

Relating Cutting Conditions Technical reference 11–33

pages (11-14 ) (14-1)