Page 854 - Tungaloy Catalog

P. 854

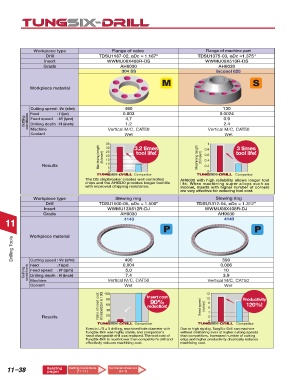

Workpiece type Flange of valve Flange of machine part

Drill TDSU1187-02, øDc = 1.187" TDSU1375-03, øDc =1.375"

Insert WWMU08X408R-DS WWMU09X510R-DS

Grade AH6030 AH6030

304 SS Inconel 625

Workpiece material

Cutting speed : Vc (sfm) 460 130

Feed : f (ipr) 0.003 0.0024

Feed speed : Vf (ipm) 4.7 0.9

Cutting conditions Drilling depth : H (inch) 1.2 2.4

Machine Vertical M/C, CAT50 Vertical M/C, CAT50

Coolant Wet Wet

35 3.2 times 0.8 1 3 times

Machining length (ft/insert) 25 tool life! Machining length (ft/insert) 0.6 tool life!

30

20

15

0.4

Results 10 5 0.2

0 0

Competitor Competitor

The DS chipbreaker creates well controlled AH6030 with high reliability allows longer tool

chips and the AH6030 provides longer tool life life. When machining super alloys such as

with improved chipping resistance. Inconel, inserts with higher number of corners

are very effective for reducing tool cost.

Workpiece type Slewing ring Slewing ring

Drill TDSU1500-05, øDc = 1.500" TDSU1312-04, øDc = 1.312"

Insert WWMU13X512R-DJ WWMU08X408R-DJ

Grade AH9030 AH9030

11 4140 4140

Drilling Tools Workpiece material

490

590

Cutting speed : Vc (sfm) 0.004 0.006

Feed

: f (ipr)

Cutting conditions Feed speed : Vf (ipm) 5.0 10

Drilling depth : H (inch) 7.4 3.9

Machine Vertical M/C, CAT50 Vertical M/C, CAT50

Coolant 100 Wet 12 Wet

Ratio of insert cost (Compettitor is 100) 80 Insert cost Feed speed (in/min) 10 8 6 Productivity

90%

120%!

60

reduction!

40

Results 20 4 2

0 0

Competitor Competitor

Even in L/D = 5 drilling, machined hole diameter with Due to high rigidity, TungSix-Drill can machine

TungSix-Drill was highly stable, and competitor's without chattering even at higher cutting speeds

head changeable drill was replaced. The tool cost of than competitors. Increased number of cutting

TungSix-Drill is much lower than competitor's drill and edge and higher productivity drastically reduces

effectively reduces machining cost. machining cost.

11–38 Relating Cutting Conditions Technical reference

pages

(11-14 )

(14-1)