Page 879 - Tungaloy Catalog

P. 879

Technical guidelines

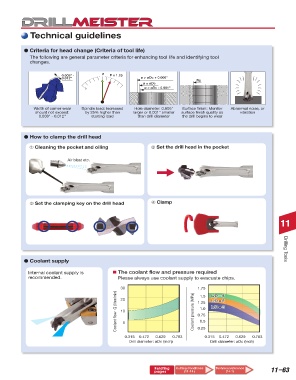

d Criteria for head change (Criteria of tool life)

The following are general parameter criteria for enhancing tool life and identifying tool

changes.

0.008" - P P x 1.25

0.012" ø > øDc + 0.006"

Ra

ø = øDc

0 ø < øDc - 0.001"

0

Width of corner wear Spindle load: Increased Hole diameter: 0.006" Surface finish: Monitor Abnormal noise, or

should not exceed: by 25% higher than larger or 0.001" smaller surface finish quality as vibration

0.008" - 0.012" starting load than drill diameter the drill begins to wear

d How to clamp the drill head

➀ Cleaning the pocket and oiling ➁ Set the drill head in the pocket

Air blast etc.

➂ Set the clamping key on the drill head ➃ Clamp

11

d Coolant supply Drilling Tools

Internal coolant supply is The coolant flow and pressure required

recommended. Please always use coolant supply to evacuate chips.

30 1.75 L/D = 8

Coolant flow Q (liter/min) 10 Coolant pressure (MPa) 1.25 L/D = 5

1.5

20

L/D = 3

1.0

0.75

0.5

5

0.315 0.472 0.629 0.783 0.25 0.315 0.472 0.629 0.783

Drill diameter: øDc (inch) Drill diameter: øDc (inch)

Relating Cutting Conditions Technical reference 11–63

pages (11-14 ) (14-1)