Page 877 - Tungaloy Catalog

P. 877

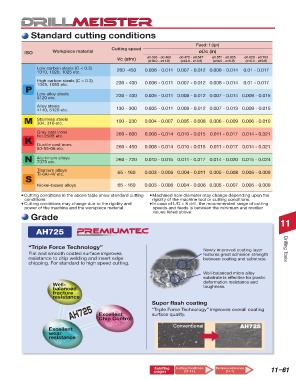

Standard cutting conditions

Feed: f (ipr)

Cutting speed

ISO Workpiece material øDc (in)

Vc (sfm) ø0.393 - ø0.468 ø0.472 - ø0.547 ø0.551 - ø0.625 ø0.629 - ø0.783

(ø10.0 - ø11.9)

(ø16.0 - ø19.9)

(ø14.0 - ø15.9)

(ø12.0 - ø13.9)

Low carbon steels (C < 0.3) 260 -450 0.006 - 0.011 0.007 - 0.012 0.008 - 0.014 0.01 - 0.017

1010, 1020, 1025 etc.

High carbon steels (C > 0.3) 230 - 400 0.006 - 0.011 0.007 - 0.012 0.008 - 0.014 0.01 - 0.017

1045, 1055 etc.

Low alloy steels 230 - 400 0.005 - 0.011 0.006 - 0.012 0.007 - 0.014 0.009 - 0.015

5120 etc.

Alloy steels 130 - 300 0.005 - 0.011 0.006 - 0.012 0.007 - 0.013 0.009 - 0.015

4140, 5120 etc.

Stainless steels 100 - 230 0.004 - 0.007 0.005 - 0.008 0.006 - 0.009 0.006 - 0.010

304, 316 etc.

Gray cast irons 260 - 600 0.008 - 0.014 0.010 - 0.015 0.011 - 0.017 0.014 - 0.021

No.250B etc.

Ductile cast irons 260 - 450 0.008 - 0.014 0.010 - 0.015 0.011 - 0.017 0.014 - 0.021

80-55-06 etc.

Aluminum alloys 260 - 720 0.010 - 0.015 0.011 - 0.017 0.014 - 0.020 0.015 - 0.024

7075 etc.

Titanium alloys 65 - 160 0.003 - 0.006 0.004 - 0.011 0.005 - 0.008 0.006 - 0.009

Ti-6Al-4V etc.

Nickel-based alloys 65 - 160 0.003 - 0.006 0.004 - 0.006 0.005 - 0.007 0.006 - 0.009

● Cutting conditions in the above table show standard cutting ● Machined hole diameter may change depending upon the

conditions. rigidity of the machine tool or cutting conditions.

● Cutting conditions may change due to the rigidity and ● In case of L/D = 8 drill, the recommended range of cutting

power of the machine and the workpiece material. speeds and feeds is between the minimum and median

values listed above.

Grade

11

AH725

“Triple Force Technology” Newly improved coating layer Drilling Tools

Flat and smooth coated surface improves features great adhesion strength

resistance to chip welding and insert edge between coating and substrate.

chipping. For standard to high speed cutting.

Well-balanced micro alloy

substrate is effective for plastic

Well- deformation resistance and

balanced toughness.

fracture

resistance

Super flash coating

“Triple Force Technology” improves overall coating

Excellent surface quality.

Chip Control

Conventional AH725

Excellent

wear

resistance

Relating Cutting Conditions Technical reference 11–61

pages (11-14 ) (14-1)