Page 51 - Aloris Catalog

P. 51

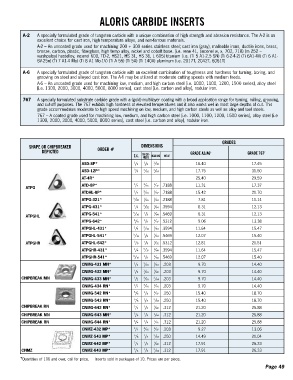

ALORIS CARBIDE INSERTS

A-2 A specially formulated grade of tungsten carbide with a unique combination of high strength and abrasion resistance. The A-2 is an

excellent choice for cast iron, high temperature alloys, and non-ferrous materials.

A-2 – An uncoated grade used for machining 200 + 300 series stainless steel; cast iron (gray), malleable irons, ductile irons, brass,

bronze, carbon, plastic, fiberglass, high temp alloy, nickel and cobalt base. [i.e. rene 41, (inconel w, x, 702, 718) (m 252 –

washpaloy) hastelloy, inconel 600, TD-2, HS21, HS 31, HS 36, L 605) titanium {i.e. (Ti 5 A1-2.5 SN) (Ti 6-2-4-2) (Ti 6A1-4V) (Ti 6 A1-

6V-25n) (Ti 7 A1-4 Mo) (Ti 8 A1 Mo-1V) (Ti A 55) (Ti 5A) (Ti 140A) aluminum (i.e. 2017T, 2042T, 6061T]

A-6 A specially formulated grade of tungsten carbide with an excellent combination of toughness and hardness for turning, boring, and

grooving on steel and alloyed cast iron. The A-6 may be utilized at moderate cutting speeds with medium feeds.

A-6 – An uncoated grade used for machining low, medium, and high carbon steel [i.e. 1000, 1100, 1200, 1500 series], alloy steel

[i.e. 1300, 2000, 3000, 4000, 5000, 8000 series], cast steel [i.e. carbon and alloy], nodular iron.

767 A specially formulated substrate carbide grade with a (gold) multi-layer coating with a broad application range for turning, milling, grooving,

and cut-off purposes. The 767 exhibits high hardness at elevated temperatures and it also works well in most large depths of cut. This

grade accommodates moderate to high speed machining on low, medium, and high carbon steels as well as alloy and tool steels.

767 – A coated grade used for machining low, medium, and high carbon steel [i.e. 1000, 1100, 1200, 1500 series], alloy steel [i.e

1300, 2000, 3000, 4000, 5000, 8000 series], cast steel [i.e. carbon and alloy], nodular iron.

GRADES

SHAPE OR CHIPBREAKER ORDER # DIMENSIONS

DEPICTED GRADE A2/A6 † GRADE 767 †

I.C. THICK- RADIUS HOLE

NESS

ASD-8P* 1 /2 1 /8 1 /32 16.40 17.45

ASD-12P* 3 /4 3 /16 3 /64 17.75 31.50

AT-4R* 25.40 29.59

ATD-8P* 1 /2 3 /16 1 /32 .7188 11.31 17.37

ATPG

ATDHL-8P* 1 /2 3 /16 1 /32 .7188 15.42 21.70

ATPG-321* 5 /32 1 /16 1 /64 .2188 7.81 11.14

ATPG-431* 1 /4 3 /32 1 /64 .3594 8.31 12.13

ATPG-541* 5 /16 1 /8 1 /64 .5469 8.31 12.13

ATPGHL

ATPG-642* 3 /8 1 /8 1 /32 .5312 9.06 13.38

ATPGHL-431* 1 /4 3 /32 1 /64 .3594 11.64 15.47

ATPGHL-541* 5 /16 1 /8 1 /64 .5469 12.07 15.40

ATPGHR ATPGHL-642* 3 /8 1 /8 1 /32 .5312 12.81 21.51

ATPGHR-431* 1 /4 3 /32 1 /64 .3594 11.64 15.47

ATPGHR-541* 5 /16 1 /8 1 /64 .5469 12.07 15.40

CNMG-431 MN* 1 /2 3 /16 1 /64 .203 9.70 14.40

CNMG-432 MN* 1 /2 3 /16 1 /32 .203 9.70 14.40

CHIPBREAK MN CNMG-433 MN* 1 /2 3 /16 3 /64 .203 9.70 14.40

CNMG-434 RN* 1 /2 3 /16 1 /16 .203 9.70 14.40

CNMG-542 RN* 5 /8 1 /4 1 /32 .250 15.40 18.70

CNMG-543 RN* 5 /8 1 /4 3 /64 .250 15.40 18.70

CHIPBREAK RN CNMG-642 RN* 3 /4 1 /4 1 /32 .312 21.20 25.88

CHIPBREAK MN CNMG-643 MN* 3 /4 1 /4 3 /64 .312 21.20 25.88

CHIPBREAK RN CNMG-644 RN* 3 /4 1 /4 1 /16 .312 21.20 25.88

CNMZ-432 MP* 1 /2 3 /16 1 /32 .203 9.27 13.06

CNMZ-543 MP* 5 /8 1 /4 3 /64 .250 14.49 21.04

CNMZ-642 MP* 3 /4 1 /4 1 /32 .312 17.91 26.33

CNMZ CNMZ-643 MP* 3 /4 1 /4 3 /64 .312 17.91 26.33

Quantities of 100 and over, call for price. Inserts sold in packages of 10. Prices are per piece.

Page 49