Page 439 - Ceratizit Catalog

P. 439

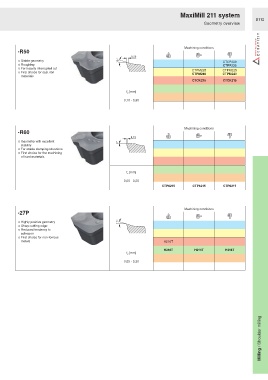

MaxiMill 211 system

B112

Geometry overview

Machining conditions

-R50

0,20

○ Stable geometry 10° CTCP230

○ Roughing

CTPP235

○ For heavily interrupted cut CTPM225 CTPM225

○ First choice for cast iron

CTPM240 CTPM240

materials

CTCK215 CTCK215

f z [mm]

0,10 - 0,30

Machining conditions

-R60

0,15

○ Geometry with excellent 0°

stability

○ For stable clamping situations

○ First choice for the machining

of hard materials

f z [mm]

0,05 - 0,20

CTP6215 CTP6215 CTP6215

Machining conditions

-27P

○ Highly positive geometry 17°

○ Sharp cutting edge

○ Reduced tendency to

adhesion

○ First choice for non-ferrous

metals H216T

H216T H216T H216T

f z [mm]

0,05 - 0,30

Milling / Shoulder milling