Page 640 - Ceratizit Catalog

P. 640

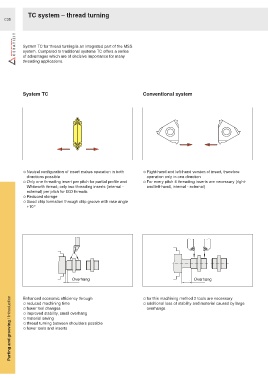

TC system – thread turning

C35

System TC for thread turning is an integrated part of the MSS

system. Compared to traditional systems TC offers a series

of advantages which are of decisive importance for many

threading applications.

System TC Conventional system

○ Neutral configuration of insert makes operation in both ○ Right-hand and left-hand version of insert, therefore

directions possible operation only in one direction

○ Only one threading insert per pitch for partial profile and ○ For every pitch 4 threading inserts are necessary (right-

Whitworth thread; only two threading inserts (internal - and left-hand, internal - external)

external) per pitch for ISO threads

○ Reduced storage

○ Good chip formation through chip groove with rake angle

+10°

Overhang

Overhang ○ for this machining method 2 tools are necessary

Parting and grooving / Introduction ○ fewer tool changes overhangs

Enhanced economic efficiency through

○ additional loss of stability and material caused by large

○ reduced machining time

○ improved stability, small overhang

○ material saving

○ thread turning between shoulders possible

○ fewer tools and inserts