Page 80 - Parlec Catalog

P. 80

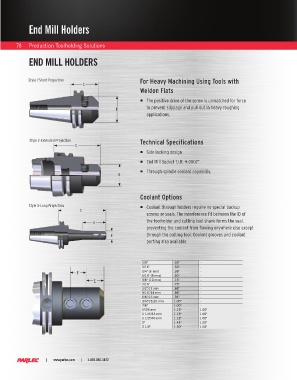

End Mill Holders

78 Production Toolholding Solutions

END MILL HOLDERS

Style 1-Short Projection For Heavy Machining Using Tools with

C

Weldon Flats

The positive drive of the screw is unmatched for force

B to prevent slippage and pull out in heavy roughing

applications.

Style 2-Extended Projection Technical Specifications

C

Side locking design

End Mill Socket T.I.R. ≤.0002”.

Through-spindle coolant capability.

B

Coolant Options

Style 3-Long Projection Coolant through holders require no special backup

C

screws or seals. The interference fit between the ID of

the toolholder and cutting tool shank forms the seal,

H

preventing the coolant from flowing anywhere else except

B through the cutting tool. Coolant grooves and coolant

porting also available.

1/8" .38" -

3/16" .50" -

F 1/4" (6 mm) .38" -

5/16" (8 mm) .60" -

E 3/8" (10 mm) .75" -

7/16" .75" -

1/2"/12 mm .88" -

9/16"/14 mm .88" -

5/8"/16 mm .94" -

3/4"/18,20 mm 1.00" -

7/8" 1.00" -

1"/25 mm 1.12" 1.00"

1 1/4"/32 mm 1.12" 1.00"

1 1/2"/40 mm 1.12" 1.00"

2" 1.41" 1.50"

2 1/2" 1.50" 1.56"

| www.parlec.com | 1-800-866-5872