Page 861 - Tungaloy Catalog

P. 861

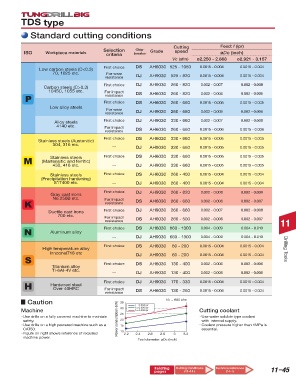

TDS type

Standard cutting conditions

Cutting Feed: f (ipr)

Selection Chip- Grade speed

ISO Workpiece materials breaker øDc (inch)

criteria

Vc (sfm) ø2.250 - 2.868 ø2.921 - 3.157

First choice DS AH6030 525 - 1050 0.0015 - 0.004 0.0015 - 0.004

Low carbon steels (C<0.3)

70, 1025 etc. For wear

resistance DJ AH9030 525 - 820 0.0015 - 0.004 0.0015 - 0.004

First choice DJ AH9030 260 - 820 0.002 - 0.007 0.002 - 0.008

Carbon steels (C>0.3)

1045C, 1055 etc. For impact

resistance DS AH6030 260 - 820 0.002 - 0.006 0.002 - 0.006

First choice DS AH6030 260 - 660 0.0015 - 0.005 0.0015 - 0.005

Low alloy steels

For wear

resistance DJ AH9030 260 - 660 0.002 - 0.006 0.002 - 0.006

First choice DJ AH9030 330 - 660 0.002 - 0.007 0.002 - 0.008

Alloy steels

4140 etc.

For impact

resistance DS AH6030 260 - 660 0.0015 - 0.006 0.0015 - 0.006

First choice DS AH6030 330 - 660 0.0015 - 0.005 0.0015 - 0.005

Stainless steels (Austenitic)

304, 316 etc.

― DJ AH9030 330 - 660 0.0015 - 0.005 0.0015 - 0.005

Stainless steels First choice DS AH6030 330 - 660 0.0015 - 0.005 0.0015 - 0.005

(Martensitic and ferritic)

430, 416 etc. ― DJ AH9030 330 - 660 0.0015 - 0.005 0.0015 - 0.005

Stainless steels First choice DS AH6030 260 - 400 0.0015 - 0.004 0.0015 - 0.004

(Precipitation hardening)

S17400 etc. ― DJ AH9030 260 - 400 0.0015 - 0.004 0.0015 - 0.004

First choice DJ AH9030 260 - 820 0.002 - 0.008 0.002 - 0.009

Gray cast irons

No.250B etc. For impact

resistance DS AH6030 260 - 660 0.002 - 0.006 0.002 - 0.007

Ductile cast irons First choice DJ AH9030 260 - 660 0.002 - 0.007 0.002 - 0.008

700 etc.

For impact 0.002 - 0.006 0.002 - 0.007

resistance DS AH6030 260 - 500 11

First choice DS AH6030 660 - 1300 0.004 - 0.009 0.004 - 0.010

Aluminum alloy

― DJ AH9030 660 - 1300 0.004 - 0.009 0.004 - 0.010

First choice DS AH6030 60 - 200 0.0015 - 0.004 0.0015 - 0.004

High temperature alloy Drilling Tools

Innconel718 etc

― DJ AH9030 60 - 200 0.0015 - 0.004 0.0015 - 0.004

First choice DS AH6030 130 - 400 0.002 - 0.006 0.002 - 0.006

Titanium alloy

Ti-6Al-4V etc.

― DJ AH9030 130 - 400 0.002 - 0.006 0.002 - 0.006

First choice DJ AH9030 170 - 330 0.0015 - 0.004 0.0015 - 0.004

Hardened steel

Over 40HRC For impact DS AH6030 130 - 260 0.0015 - 0.004 0.0015 - 0.004

resistance

Caution 35 f = 0.004 ipr Vc = 600 sfm

f = .004 ipr

f = .006 ipr

Machine 30 f = 0.006 ipr Cutting coolant

f = .008 ipr

f = 0.008 ipr

Use drills on a fully covered machine to maintain 25 Use water soluble type coolant

safety. Power consumption (kW) 20 with internal supply.

Use drills on a high powered machine such as a 15 Coolant pressure higher than 1MPa is

CAT50. essential.

Figure on right shows reference of required 10 2.2 2.4 2.6 2.8 3 3.2

machine power.

Tool diameter: øDc (inch)

Relating Cutting Conditions Technical reference 11–45

pages (11-14 ) (14-1)