Page 865 - Tungaloy Catalog

P. 865

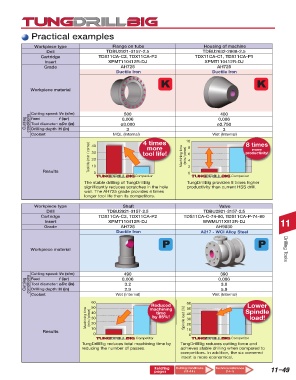

Practical examples

Workpiece type Flange on tube Housing of machine

Drill TDBU2921-3157-2.5 TDBU2632-2868-2.5

Cartridge TDX11CA-C2, TDX11CA-P2 TDX11CA-C1, TDX11CA-P1

Insert XPMT110412R-DJ XPMT110412R-DJ

Grade AH725 AH725

Ductile Iron Ductile Iron

Workpiece material

Feed: f (ipr) 500 400

Cutting speed: Vc (sfm)

Cutting conditions Tool diameter: øDc (in) ø3.000 ø2.750

0.006

0.006

3

Drilling depth: H (in)

3

Coolant 40 MQL (Internal) 4 times 10 Wet (Internal) 8 times

Tool life (min / corner) 30 tool life! Machining time (min / piece) 8 6 4 productivity!

more

more

20

Results 10 2 0

0

Competitor Competitor

The stable drilling of TungDrillBig TungDrillBig provides 8 times higher

significantly reduces scratches in the hole productivity than current HSS drill.

wall. The AH725 grade provides 4 times

longer tool life than its competitors.

Workpiece type Shaft Valve

Drill TDBU2921-3157-2.5 TDBU2921-3157-2.5

Cartridge TDX11CA-C2, TDX11CA-P2 TDS11CA-C-74-80, TDS11CA-P-74-80

Insert XPMT110412R-DJ WWMU11X512R-DJ 11

Grade AH725 AH9030

Ductile Iron A217 - WCI Alloy Steel

Workpiece material Drilling Tools

Cutting speed: Vc (sfm) 490 390

Feed: f (ipr) 0.006 0.006

Cutting conditions Tool diameter: øDc (in) 3.2 3.0

2.9

5.9

Drilling depth: H (in)

Coolant Wet (Internal) Wet (Internal)

60 60

Lower

Reduced 50 Spindle

Machining time (min / piece) 40 by 85%! Spindle load (%) 40 load!

50

machining

time

30

30

20

20

Results 10 10

0 0

Competitor Competitor

TungDrillBig reduces total machining time by TungDrillBig reduces cutting force and

reducing the number of passes. achieves stable drilling when compared to

competitors. In addition, the six cornered

insert is more economical.

Relating Cutting Conditions Technical reference 11–49

pages (11-14 ) (14-1)