Page 862 - Tungaloy Catalog

P. 862

TDX type

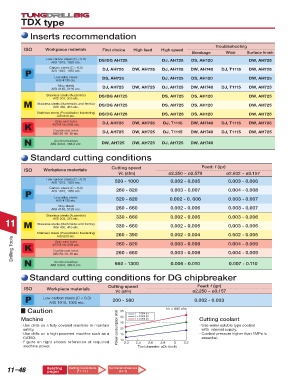

Inserts recommendation

Troubleshooting

ISO Workpiece materials First choice High feed High speed

Breakage Wear Surface finish

Low carbon steels (C < 0.3) DS/DG AH725 DJ, AH725 DS, AH120 DW, AH725

AISl 1015, 1025 etc.

Carbon steels (C > 0.3) DJ, AH725 DW, AH725 DJ, AH725 DW, AH740 DJ, T1115 DW, AH725

AISl 1045, 1055 etc.

Low alloy steels DS, AH725 DJ, AH725 DS, AH120 DW, AH725

AISl 4130 etc.

Alloy steels DJ, AH725 DW, AH725 DJ, AH725 DW, AH740 DJ, T1115 DW, AH725

AISl 4140, 5120 etc.

Stainless steels (Austenitic) DS/DG AH725 DS, AH725 DS, AH120 DW, AH725

AISl 304, 316 etc.

Stainless steels (Martensitic and ferritic) DS/DG AH725 DS, AH725 DS, AH120 DW, AH725

AISl 430, 416 etc.

Stainless steels (Precipitation hardening) DS/DG AH725 DS, AH725 DS, AH120 DW, AH725

AISl 630 etc.

Gray cast irons

ASTM No.35B etc. DJ, AH725 DW, AH725 DJ, T1115 DW, AH740 DJ, T1115 DW, AH725

Ductile cast irons DJ, AH725 DW, AH725 DJ, T1115 DW, AH740 DJ, T1115 DW, AH725

AISI 60-40-18 etc.

Aluminum alloys

AISl 333.0, 383.0 etc. DW, AH725 DW, AH725 DJ, AH725 DW, AH740

Standard cutting conditions

Cutting speed Feed: f (ipr)

ISO Workpiece materials

Vc (sfm) ø2.250 ~ ø2.579 ø2.632 ~ ø3.157

Low carbon steels (C < 0.3)

AISl 1015, 1025 etc. 520 - 1000 0.002 - 0.005 0.003 - 0.006

Carbon steels (C > 0.3)

AISl 1045, 1055 etc. 260 - 820 0.003 - 0.007 0.004 - 0.008

Low alloy steels

AISl 4130 etc. 520 - 820 0.002 - 0. 006 0.003 - 0.007

Alloy steels

AISl 4140, 5120 etc. 260 - 660 0.002 - 0.006 0.003 - 0.007

Stainless steels (Austenitic) 330 - 660 0.002 - 0.005 0.003 - 0.006

AISl 304, 316 etc.

11 Stainless steels (Martensitic and ferritic)

AISl 430, 416 etc. 330 - 660 0.002 - 0.005 0.003 - 0.006

Stainless steels (Precipitation hardening) 260 - 390 0.002 - 0.004 0.002 - 0.005

AISl 630 etc.

Drilling Tools ASTM No.35B etc. 260 - 820 0.003 - 0.008 0.004 - 0.009

Gray cast irons

Ductile cast irons

260 - 660

0.003 - 0.008

0.004 - 0.009

AISI 60-40-18 etc.

Aluminum alloys

AISl 333.0, 383.0 etc. 660 - 1300 0.006 - 0.010 0.007 - 0.110

Standard cutting conditions for DG chipbreaker

Cutting speed Feed: f (ipr)

ISO Workpiece materials

Vc (sfm) ø2.250 ~ ø3.157

Low carbon steels (C < 0.3)

200 - 580 0.002 - 0.003

AISI 1010, 1025 etc.

Caution 35 f = 0.004 ipr Vc = 600 sfm

f = .004 ipr

f = 0.006 ipr

Machine 30 f = .006 ipr Cutting coolant

f = .008 ipr

f = 0.008 ipr

Use drills on a fully covered machine to maintain 25 Use water soluble type coolant

safety. Power consumption (kW) 20 with internal supply.

Use drills on a high powered machine such as a 15 Coolant pressure higher than 1MPa is

CAT50. essential.

Figure on right shows reference of required 10 2.2 2.4 2.6 2.8 3 3.2

machine power. Tool diameter: øDc (inch)

11–46 Relating Cutting Conditions Technical reference

pages

(14-1)

(11-14 )