Page 866 - Tungaloy Catalog

P. 866

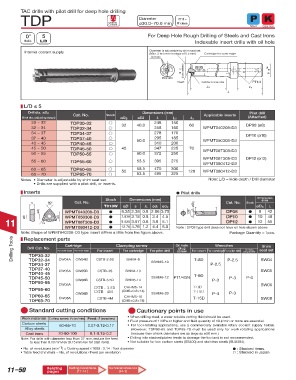

TAC drills with pilot drill for deep hole drilling

TDP Internal Diameter IT class Steel Cast lron

IT11~

ø30.0~70.0 mm

Coolant

0° 5 For Deep Hole Rough Drilling of Steels and Cast Irons

Helix L/D Indexable insert drills with oil hole

Internal coolant supply Diameter is adjustable by shim seat set. Cartridge for outer edge

(Max. 2 to 5 mm in steps of 0.5 mm)

Oil hole

(Cutter diameter)

c 2 s h6

ø ø ø

Pilot drill

Insert Cartridge for inner edge PT1/4

L2 R S

L

L/D ≤ 5

Drill dia. øDc Dimensions (mm) Pilot drill

Cat. No. Stock Applicable inserts

(Tool dia. adjusting range) øDs øD2 L L2 R s (Attached)

30 ~ 32 TDP30-32 248 150

32 ~ 34 TDP32-34 32 40.0 258 160 60 WPMT040208-D3 DP08 (ø8)

34 ~ 37 TDP34-37 278 170 DP10 (ø10)

37 ~ 40 TDP37-40 50.0 295 185 WPMT050308-D3

40 ~ 45 TDP40-45 310 200

45 ~ 50 TDP45-50 40 347 225 70

50 ~ 55 TDP50-55 60.0 372 250 WPMT06T308-D3

WPMT06T308-D3 DP12 (ø12)

55 ~ 60 TDP55-60 53.5 395 275 WPMT080412-D3

60 ~ 65 TDP60-65 50 58.5 470 300 120 WPMT080412-D3

65 ~ 70 TDP65-70 63.5 495 325

Notes • Diameter is adjustable by shim seat set. Note: L/D = Hole depth / Drill diameter

• Drills are supplied with a pilot drill, or inserts.

Inserts Pilot drills

Stock Dimensions (mm) Dimensions

(mm)

s 80° Cat. No. øDc Cat. No. Stock

T313W øD s r ε ød1 ød2 øDc L

ød2 WPMT040208-D3 6.35 2.38 0.8 2.86 3.75 138° DP08 8 42

ød1 øD WPMT050308-D3 7.938 3.18 0.8 3.4 4.5 DP10 10 48

11 r ε WPMT06T308-D3 9.525 3.97 0.8 3.9 5.1 Note : DP08 type drill does not have oil hole shown above. 55

12

DP12

12.70 4.76 1.2 4.4 6.0

WPMT080412-D3

Note: Shape of WPMT040208-D3 type insert differs a little from the figure above. Package Quantity = 1pcs.

Drilling Tools Drill Cat. No. For outer edge For inner edge For insert Clamping screw For pilot drill Oil hole For insert For cartridgeFor pilot drill plug screw seat set

Replacement parts

Wrenches

Cartridge

Shim

plug

For cartridge

Oil hole

screw

TDP30-32

TDP32-34

TDP34-37 CW04A CW04B CSTB-2.5S BHM4-8 SSHM5-10 T-8D P-2.5 P-2.5 SW04

TDP37-40 CW05A CW05B CSTB-3S BHM4-10 SW05

TDP40-45

TDP45-50 CW06B CSTB-3.5D BHM5-14 SSHM6-12 PT1/4GN T-9D P-3 P-3 P-6

TDP50-55 CW06A SW06

CHHM5-14

TDP55-60 CSTB - 3.5D (CM5×0.8×14) T-9D

CSTB - 4M

T-15D

TDP60-65 CW08A CW08B CHHM5-18 SSHM6-20 T-15D P-4 P-3

TDP65-70 CSTB-4M (CM5×0.8×18) SW08

Standard cutting conditions Cautionary points in use

• When drilling steel, a water soluble cutting fluid should be used.

Work materials Cutting speed: Vc (m/min) Feed: f (mm/rev)

Carbon steels • Fluid pressure of 1 MPa or higher and fluid quantity of 10R /min or more are essential.

60-65-70 0.07-0.12-0.17 • For tool-rotating applications, use a commercially available rotary coolant supply holder.

Alloy steels (However, TDP60-65 and TDP65-70 must be used only for work rotating applications

Cast irons 70-80-100 0.1-0.15-0.2 because their shank diameters are as large as ø50 mm.)

Note: For drills with diameter less than 37 mm, reduce the feed • Drilling into stacked plates tends to damage the tool and is not recommended.

to less than 0.13 mm/rev (0.15 mm/rev for cast irons). • Not suitable for low carbon steels (SS400) and stainless steels (SUS304).

• No. of revolutions (min -1 ) = Cutting speed10003.14Tool diameter : Stocked items.

• Table feed (mm/min) = No. of revolutionsFeed per revolution : Stocked in Japan

11–50 Relating Cutting Conditions Technical reference

pages

(14-1)

(11-14 )