Page 867 - Tungaloy Catalog

P. 867

Reduces setup time!

Simplifies the drilling and chamfering process!

New drilling system drastically improves productivity!

Easy operation: Improves accuracy,

rigidity and productivity

- Unique clamping structure provides high rigidity and repeatability.

- Easy operation; Head can be changed on the machine without the need to check

tool length offset, reducing tool indexing time.

Drill head Drill body

Contact areas that support drill

head against the cutting force

Contact areas that maintain the

accuracy of drill

Improved drill body durability

- New clamping system increases the number of head indexing cycles.

- High durability reduces head damage.

11

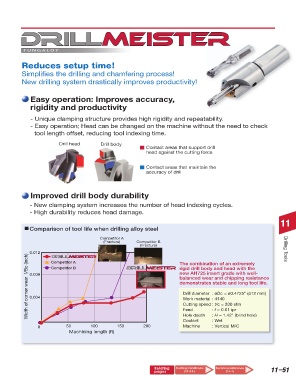

Comparison of tool life when drilling alloy steel

Competitor A

(Fracture) Competitor B

(Fracture)

0.012 Competitor A The combination of an extremely Drilling Tools

Width of corner wear VBc (inch) 0.008 new AH725 insert grade with well-

rigid drill body and head with the

Competitor B

balanced wear and chipping resistance

demonstrates stable and long tool life.

: øDc = ø0.4725" (ø12 mm)

Drill diameter

0.004

Work material

: 4140

Cutting speed

Feed

: f = 0.01 ipr

: H = 1.42" (blind hole)

Hole depth

: Wet

Coolant : Vc = 330 sfm

0 50 100 150 200 Machine : Vertical M/C

Machining length (ft)

Relating Cutting Conditions Technical reference 11–51

pages (11-14 ) (14-1)