Page 149 - All Industrial Tool Supply | General Catalog

P. 149

Cobalt Jobbers • DRILLS

147

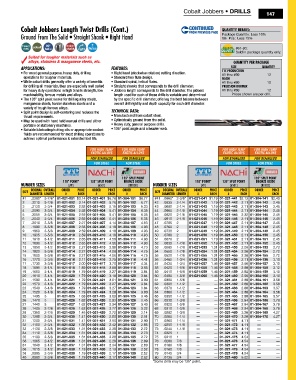

Cobalt Jobbers Length Twist Drills (Cont.) QuanTiTy BreakS:

Ground From The Solid • Straight Shank • Right Hand Package Quantity: Less 10%

60+ Pcs.: Less 15%

#61-80:

Sold in package quantity only.

Suited for tougher materials such as

alloys, stainless & manganese steels, etc. QuanTiTy Per PaCkage

APPLICATIONS: FeATureS: Size QuanTiTy

• For most general purpose, heavy duty, drilling • Right hand (clockwise rotation) cutting direction. TTC ProDuCTion 12

#1 thru #60

operations for tougher materials. • Standard two flute design. naChi

• While cobalt drills generally offer a variety of benefits • Standard spiral, helical flutes. #1 thru #80 10

for drilling all materials, they are especially well suited • Straight shanks that corresponds to the drill diameter. PreCiSion Dormer

for heavy duty operations in high tensile strength, low • Jobbers length corresponds to the drill diameter. The jobbers #1 thru #80 12

machinability, ferrous metals and alloys. length used for each of these drills is variable and determined Prices shown are per drill.

• The 135° split point works for drilling alloy steels, by the specific drill diameter, offering the best balance between

manganese steels, harder stainless steels and a overall drill rigidity and depth capacity for each drill diameter.

variety of tough ferrous alloys.

• Split point design is self-centering and reduces the TeChNICAL DATA:

thrust requirements. • Manufactured from cobalt steel.

• May be used with hand held manual drills and either • Cylindrically ground from the solid.

portable or stationary machines. • Heavy duty, general purpose drills.

• Suitable lubricating/cutting oils or appropriate coolant • 135° point angle and a heavier web.

fluids are recommended for most drilling operations to

achieve optimal performance & extended tool life.

FOR HIGH TEMP FOR HIGH TEMP FOR HIGH TEMP FOR HIGH TEMP

EXOTIC ALLOYS EXOTIC ALLOYS EXOTIC ALLOYS EXOTIC ALLOYS

FOR STAINLESS FOR STAINLESS FOR STAINLESS FOR STAINLESS

FOR STEEL FOR STEEL FOR STEEL FOR STEEL

135° SPLiT PoinT 135° SPLiT PoinT

118° PoinT* 135° SPLiT PoinT Bronze oxiDe 118° PoinT* 135° SPLiT PoinT Bronze oxiDe

numBer SizeS [A9] [6501] [R18CO] numBer SizeS [A9] [6501] [R18CO]

DeCimaL overaLL orDer PriCe orDer PriCe orDer PriCe DeCimaL overaLL orDer PriCe orDer PriCe orDer PriCe

Size Size

DiameTer LengTh # eaCh # eaCh # eaCh DiameTer LengTh # eaCh # eaCh # eaCh

#1 .2280" 3-7/8" 01-021-001 $3.14 01-021-401 $5.76 01-304-101 $6.77 #41 .0960" 2-3/8" 01-021-041 $1.19 01-021-441 $2.13 01-304-141 $2.49

2 .2210 3-7/8 01-021-002 3.14 01-021-402 5.76 01-304-102 6.77 42 .0935 2-1/4 01-021-042 1.19 01-021-442 2.11 01-304-142 2.45

3 .2130 3-3/4 01-021-003 2.92 01-021-403 5.16 01-304-103 6.33 43 .0890 2-1/4 01-021-043 1.19 01-021-443 2.11 01-304-143 2.45

4 .2090 3-3/4 01-021-004 2.92 01-021-404 5.41 01-304-104 6.35 44 .0860 2-1/8 01-021-044 1.19 01-021-444 2.11 01-304-144 2.45

5 .2055 3-3/4 01-021-005 2.92 01-021-405 5.41 01-304-105 6.35 45 .0820 2-1/8 01-021-045 1.19 01-021-445 2.32 01-304-145 2.45

6 .2040 3-3/4 01-021-006 2.92 01-021-406 5.41 01-304-106 6.35 46 .0810 2-1/8 01-021-046 1.19 01-021-446 2.11 01-304-146 2.45

7 .2010 3-5/8 01-021-007 2.27 01-021-407 4.14 01-304-107 4.93 47 .0785 2 01-021-047 1.19 01-021-447 2.11 01-304-147 2.45

8 .1990 3-5/8 01-021-008 2.33 01-021-408 4.18 01-304-108 4.93 48 .0760 2 01-021-048 1.19 01-021-448 2.11 01-304-148 2.45

9 .1960 3-5/8 01-021-009 2.59 01-021-409 4.18 01-304-109 4.93 49 .0730 2 01-021-049 1.19 01-021-449 2.11 01-304-149 2.45

10 .1935 3-5/8 01-021-010 2.59 01-021-410 4.18 01-304-110 4.93 50 .0700 2 01-021-050 1.19 01-021-450 2.11 01-304-150 2.45

11 .1910 3-1/2 01-021-011 2.65 01-021-411 4.56 01-304-111 4.93 51 .0670 2 01-021-051 1.19 01-021-451 2.11 01-304-151 2.45

12 .1890 3-1/2 01-021-012 2.65 01-021-412 4.56 01-304-112 4.93 52 .0635 1-7/8 01-021-052 1.19 01-021-452 2.11 01-304-152 2.45

13 .1850 3-1/2 01-021-013 2.27 01-021-413 3.98 01-304-113 4.73 53 .0595 1-7/8 01-021-053 1.31 01-021-453 2.28 01-304-153 2.72

14 .1820 3-3/8 01-021-014 2.27 01-021-414 4.06 01-304-114 4.75 54 .0550 1-7/8 01-021-054 1.31 01-021-454 2.28 01-304-154 2.72

15 .1800 3-3/8 01-021-015 2.27 01-021-415 4.06 01-304-115 4.75 55 .0520 1-7/8 01-021-055 1.31 01-021-455 2.28 01-304-155 2.72

16 .1770 3-3/8 01-021-016 2.11 01-021-416 3.75 01-304-116 4.41 56 .0465 1-3/4 01-021-056 1.31 01-021-456 2.11 01-304-156 3.10

17 .1730 3-3/8 01-021-017 2.00 01-021-417 3.70 01-304-117 4.34 57 .0430 1-3/4 01-021-057 1.46 01-021-457 2.56 01-304-157 3.10

18 .1695 3-1/4 01-021-018 1.89 01-021-418 3.68 01-304-118 3.95 58 .0420 1-5/8 01-021-058 1.46 01-021-458 2.80 01-304-158 3.12

19 .1660 3-1/4 01-021-019 1.79 01-021-419 3.27 01-304-119 3.84 59 .0410 1-5/8 01-021-059 1.46 01-021-459 2.88 01-304-159 3.10

20 .1610 3-1/4 01-021-020 1.79 01-021-420 3.16 01-304-120 3.84 60 .0400 1-5/8 01-021-060 1.46 01-021-460 2.56 01-304-160 3.10

21 .1590 3-1/4 01-021-021 1.79 01-021-421 3.01 01-304-121 3.80 61 .0390 1-5/8 — — 01-021-461 2.80 01-304-161 3.58

22 .1570 3-1/8 01-021-022 1.79 01-021-422 3.27 01-304-122 3.84 62 .0380 1-1/2 — — 01-021-462 2.80 01-304-162 3.58

23 .1540 3-1/8 01-021-023 1.79 01-021-423 3.27 01-304-123 3.84 63 .0370 1-1/2 — — 01-021-463 2.80 01-304-163 3.57

24 .1520 3-1/8 01-021-024 1.79 01-021-424 3.28 01-304-124 3.80 64 .0360 1-1/2 — — 01-021-464 2.80 01-304-164 3.58

25 .1495 3 01-021-025 1.68 01-021-425 3.00 01-304-125 3.46 65 .0350 1-1/2 — — 01-021-465 2.80 01-304-165 3.57

26 .1470 3 01-021-026 1.62 01-021-426 2.93 01-304-126 3.45 66 .0330 1-3/8 — — 01-021-466 2.94 01-304-166 3.79

27 .1440 3 01-021-027 1.62 01-021-427 2.94 01-304-127 3.43 67 .0320 1-3/8 — — 01-021-467 2.94 01-304-167 3.78

28 .1405 2-7/8 01-021-028 1.62 01-021-428 2.77 01-304-128 3.22 68 .0310 1-3/8 — — 01-021-468 2.94 01-304-168 3.78

29 .1360 2-7/8 01-021-029 1.46 01-021-429 2.72 01-304-129 3.14 69 .0292 1-3/8 — — 01-021-469 3.20 01-304-169 4.27

30 .1285 2-3/4 01-021-030 1.41 01-021-430 2.50 01-304-130 2.91 70 .0280 1-1/4 — — 01-021-470 3.20 01-304-170 4.27

31 .1200 2-3/4 01-021-031 1.41 01-021-431 2.50 01-304-131 2.90 71 .0260 1-1/4 — — 01-021-471 4.11 — —

32 .1160 2-3/4 01-021-032 1.36 01-021-432 2.42 01-304-132 2.85 72 .0250 1-1/8 — — 01-021-472 4.11 — —

33 .1130 2-5/8 01-021-033 1.31 01-021-433 2.38 01-304-133 2.72 73 .0240 1-1/8 — — 01-021-473 4.11 — —

34 .1110 2-5/8 01-021-034 1.31 01-021-434 2.38 01-304-134 2.73 74 .0225 1 — — 01-021-474 4.11 — —

35 .1100 2-5/8 01-021-035 1.31 01-021-435 2.28 01-304-135 2.72 75 .0210 1 — — 01-021-475 4.54 — —

36 .1065 2-1/2 01-021-036 1.31 01-021-436 2.28 01-304-136 2.69 76 .0200 7/8 — — 01-021-476 4.54 — —

37 .1040 2-1/2 01-021-037 1.31 01-021-437 2.34 01-304-137 2.69 77 .0180 7/8 — — 01-021-477 4.54 — —

38 .1015 2-1/2 01-021-038 1.19 01-021-438 2.13 01-304-138 2.52 78 .0160 7/8 — — 01-021-478 4.54 — —

39 .0995 2-3/8 01-021-039 1.19 01-021-439 2.17 01-304-139 2.52 79 .0145 3/4 — — 01-021-479 4.54 — —

40 .0980 2-3/8 01-021-040 1.19 01-021-440 2.17 01-304-140 2.52 80 .0135 3/4 — — 01-021-480 5.02 — —

*Some drills may be 135° point.